Case Study: Perth Arena, Australia

Other News

Other News Subscribe to FREE newsletter

Subscribe to FREE newsletter

| Aug 20, 2021 |

Project Summary

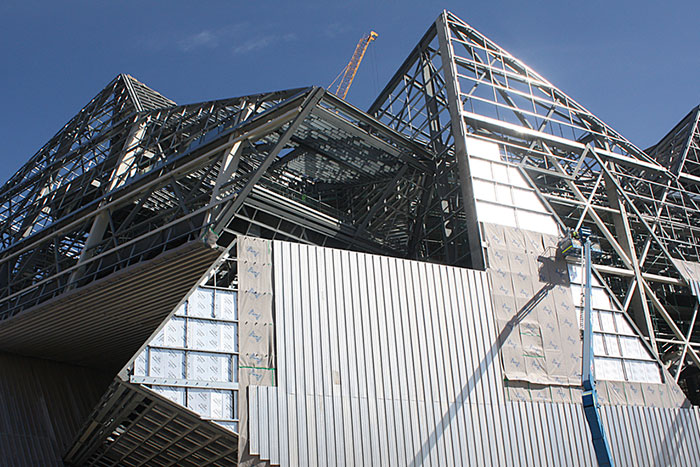

Perth Arena, a showpiece of contemporary Australian public architecture, presented Kingspan Insulation with a range of technical challenges requiring highly customized solutions. With its asymmetrical lines and sweeping irregular shapes, Perth Arena, completed in November 2012, is an individualistic building featuring a unique set of design and engineering challenges, none more dramatic than those relating to the insulation of the structure.Standing some 64 feet high, the arena is a multipurpose center built to host sporting, theatrical and musical events for up to 15,000 guests. The original and innovative design called for custom design of all basic structural elements, including insulation, to meet ambitious thermal performance targets and ensure the long-term integrity of the structure.

Even at the earliest design stages it was clear that high-performance insulation would be intrinsic to the building’s overall viability. There were two primary insulation-related considerations: how to minimize the risk of condensation; and how to achieve high thermal efficiency (System R-value of 15.33).

“It’s a large steel structure with a unique construction, and there were challenges in relation to condensation and the high R-values that were required within the building systems,” says Craig Burr, Kingspan Insulation’s State Manager WA.

Approximately 7,937 tons of steel were used to construct the arena, which is significant because large masses of cold steel within a building fabric can lead to temperature differentials between the steel and ambient air, leading to a build-up of condensation. The problem is compounded in the structural skins of energy-efficient buildings, as leaky ventilation points are tightened to minimize energy wastage. “So, there was a concern about ‘cold bridging’, or the effect that steel would have with that high insulation barrier,” Craig says.

Proprietary Solution

Fortunately, by analyzing the building’s physical and geographical characteristics, as well as the behavior of all relevant associated wall materials, it was possible to derive a solution to the threat of condensation without sacrificing thermal performance.

Craig explains, “We were able to advise about how to reduce condensation, taking into account all the building elements for that envelope. We advised about where to place our insulation on the envelope, and we also recommended that a vapor-permeable membrane would be best utilized to wrap the building before the aluminium cladding was installed on the outside. So, we offered a full-layer system from external to internal, showing where the insulation should be placed within that system.”

The resulting full-wall profile, which includes Kingspan Kooltherm K12 Framing Board rigid insulation panels, is a unique system – designed specifically for the arena – which promotes passive vapor expulsion even though the system is sealed.

“Achieving a satisfactory design for the insulated walls was only one of the practical challenges associated with this project,” Craig adds. “Due to the many irregular shapes incorporated into the façade, it was necessary to pre-cut as many K12 insulation panels as possible to guarantee correct sizing and facilitate speedy installation processes for the builder BGC Construction. As part of this process, panels were given ‘friction fit’ placement before being secured against steel surfaces with specially designed brackets.”

“We worked out that 70% of all insulation panels fitted into three distinct sizes,” Craig says, “and these were all supplied custom-cut; in the end we installed approximately 18,298 square feet of Kooltherm K12 insulation.” Overall, many thousands of separate insulation panels and strips were required to complete the project.

In the months since completion of the project, Craig reports: “The building insulation has performed to specification and there have been no reports of condensation build-up.” Kingspan Insulation’s technical expertise and project-specific solution solved the condensation problem while safeguarding energy efficiency: a performance worthy of a standing ovation.

@KingspanIns_US #KingspanIns_US #Kingspan #Insulation #MoistureManagement

For other relevant searches, you might want to try: