Alpine SnowGuards' HeatDefender: Boosting Efficiency and Longevity of Rooftop Heat Trace Cable

July 17, 2025

The HeatDefender is a heat cable housing that increases the efficiency and lifespan of rooftop heat trace cable. The two-part aluminum extrusion increases the output of rooftop heat trace cable while protecting it from exposure to the elements. The HeatDefender will increase the area of meltwater and maintain water exit channels, preventing ice dams from forming on a roof eave and gutter.

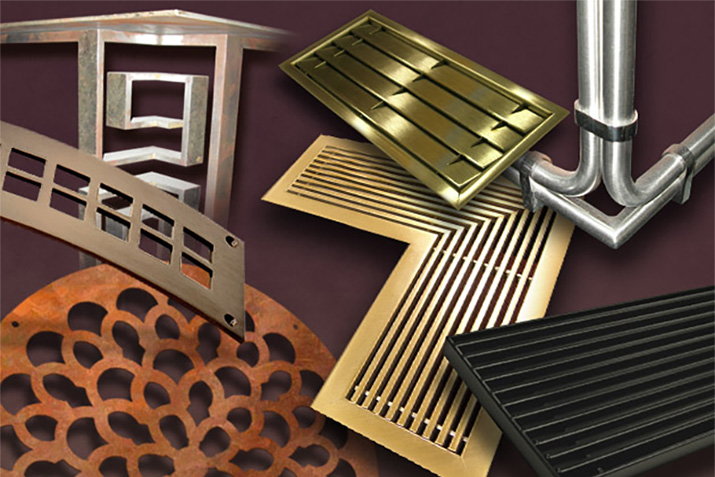

Custom Metalcraft Solutions by Coco Architectural Grilles & Metalcraft

July 10, 2025

Discover the art of custom metal fabrication with Coco Architectural Grilles & Metalcraft. With over a century of experience, Coco Architectural combines traditional craftsmanship with cutting-edge technology to deliver bespoke metal products tailored to diverse customer needs. Specializing in stainless steel fabrication, laser and waterjet cutting services, and custom metal corner guards, we offer a wide range of products including convector enclosures, wall panels, kick plates, desks, tables, and much more. Our expertise and state-of-the-art equipment ensure limitless possibilities for your metalwork projects.

The Ultimate Guide to Exterior Wall Cladding: Benefits, Materials, and Installation Tips by EQUITONE

July 8, 2025

Looking to enhance your building’s exterior? Our latest guide dives deep into the benefits, materials, and installation tips for exterior wall cladding. From aesthetic appeal to durability and energy efficiency, discover how EQUITONE’s high-quality fiber cement panels can elevate your design and performance. Read the full guide now to learn more about how the right cladding can transform your project!

Resilient Poolside Paradises: TerraCast® Planters Redefine Durability

June 26, 2025

Transform your poolside oasis with TerraCast® resin planters, designed to withstand harsh UV rays, moisture, and chlorine. Crafted from UV-stabilized resin, these planters resist fading, chipping, and corrosion, ensuring long-lasting beauty and structural integrity. Elevate your poolside landscape with TerraCast®—where durability meets timeless elegance.

New mobile full-height turnstile specifically designed for dynamic and demanding temporary deployments

June 24, 2025

Boon Edam Inc., a global leader in physical security entrance products, introduces the Turnlock 100 Mobile Platform, a new mobile security solution combining the proven performance of a Boon Edam full-height turnstile with a heavy-duty, forklift-ready base for easy transportation and deployment. Designed to be moved and redeployed as site conditions evolve, this portable security solution provides a fast, effective way to secure construction jobsites or temporary venues with the highest levels of durability, strength and safety while maintaining compliance.

Enhancing the Mail Experience for Residents with Centralized Mailbox Solutions

June 19, 2025

When designing residential communities, mailbox solutions should not be an afterthought. Florence Corporation, with over 90 years of expertise, offers comprehensive, USPS-approved centralized mailbox systems that enhance efficiency, security, and community aesthetics. From strategic location selection to compliance with regulatory standards, Florence ensures a seamless experience for both residents and property managers. Learn more about how to improve the mail and package experience in your community with our expert planning guide.

Titus Introduces CDP Cable-Operated Dampers for Linear Plenums and Round Ducts

June 17, 2025

Titus, a trusted leader in air distribution solutions, has officially launched its new CDP Cable-Operated Dampers, engineered for use with Titus linear plenums and round ducts. These innovative dampers provide precise airflow control while offering installers and technicians convenient access and streamlined adjustment.

Miller Edge: Customizable and Reliable Sensing Edges for Safety Solutions

June 12, 2025

When it comes to industrial safety, having reliable, customizable solutions on hand can make all the difference. Miller Edge’s sensing edges are designed to be versatile and easily assembled on-site, allowing for quick, efficient installations without the usual lead times. These touch-sensitive switches provide crucial safety functions, from activating emergency stops to protecting machinery. Whether you're retrofitting existing systems or installing new ones, Miller Edge offers a wide range of customizable options to meet the needs of any project, no matter how complex. Read on to learn how Miller Edge’s innovative sensing edges can enhance safety, improve efficiency, and streamline your operations.

Total Security Solutions: Enhancing Government Building Security

June 10, 2025

Maximizing the impact of safety upgrades involves setting clear goals, consulting security experts early in the planning stages, and bundling upgrades across departments to leverage economies of scale. Real-world examples highlight successful collaborations with government agencies, demonstrating practical approaches to security challenges. Total Security Solutions provides customized security solutions designed to meet stringent safety standards, including UL 752 and ASTM requirements. Their expertise ensures tailored solutions that fit operational needs and budgetary constraints.

Product Spotlight: Introducing New Sanded Rustic Colors by The Belden Brick Company

June 6, 2025

The Belden Brick Company, renowned for its commitment to quality and innovation, expands its distinguished Sanded Rustic collection with the introduction of two exclusive colors: Dusty Gray and Rustic Gray. These new hues are meticulously crafted to meet the rising demand for natural, neutral tones in contemporary architectural design.

Combatting Vandalism with TerraCast® Graffiti-Resistant Products

June 3, 2025

Vandalism poses a constant challenge for outdoor infrastructure, especially during summer when graffiti and other damage peak. Traditional materials like steel, aluminum, or fiberglass are susceptible, requiring extensive maintenance and repair. TerraCast® offers a durable solution with its vandalism-resistant LLDPE resin products.

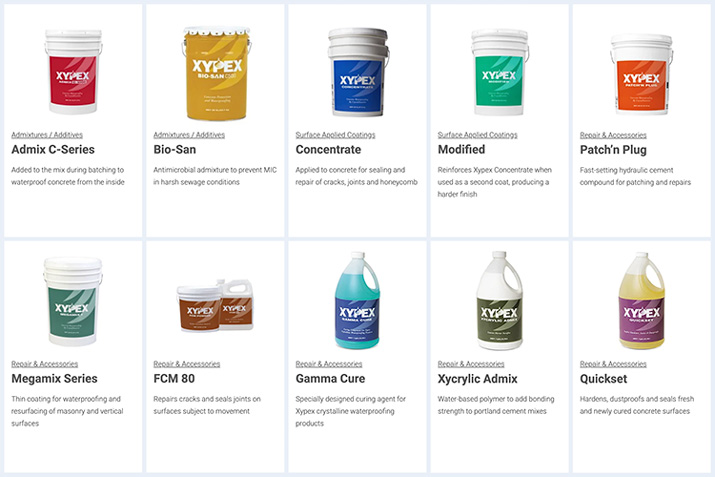

Xypex Concrete Waterproofing Products

May 30, 2025

Whether used as admixtures and added directly to cast-in-place concrete, shotcrete and precast concrete, or as surface-applied coatings, Xypex Crystalline Technology products are recognized for their versatility in solving concrete waterproofing challenges. Proven in thousands of applications in diverse construction projects and environments, Xypex products are specified and requested throughout the construction industry by engineers, architects and contractors for the permanent protection of all types of concrete.

Precision Engineering: Ruskin's Tailored Dampers for Every Application

May 28, 2025

From light operations to heavy-duty industrial applications and from backdraft control to indoor air quality control, Ruskin provides the perfect control damper. Every damper is built with performance in mind and tested per AMCA standards in Ruskin's Laboratory. Ruskin works with a variety of materials, including galvanized steel, stainless steel, aluminum and fiberglass to match your exact specifications. By molding and forming these materials, Ruskin constructs the perfect damper for your needs.

Product Spotlight: Vision Control® IGUs in Healthcare Settings

May 21, 2025

In today’s dynamic healthcare environments, patient monitoring and privacy are paramount concerns. Vision Control® insulating glass units (IGUs) from Unicel Architectural provide a sophisticated solution tailored for nurse alcoves and critical care areas. These IGUs empower healthcare professionals with discreet observation capabilities, ensuring patient safety and dignity remain uncompromised.

StoVentec® Partners with RIB SpecLink, Making Specification Faster and Easier

May 15, 2025

Sto Corp., the innovative world leader in claddings, air barriers, coatings, and restoration systems, is now featured within RIB Software’s SpecLink product, the go-to cloud-based construction specification software trusted by AEC professionals to simplify and accelerate construction documentation. As part of this collaborative effort, Sto Corp.’s StoVentec® Rainscreen® System now has a dedicated specification section in SpecLink, providing enhanced visibility and making it easier for architects and specifiers to incorporate Sto’s solutions into their project documents with accuracy and confidence.

How to Choose Slat Wall Panels for Your Room Upgrade

May 13, 2025

Slat wall panels, inspired by traditional Japanese design, have become a timeless feature in modern interiors. With a variety of sizes and materials, from mini slats for minimalist spaces to large slats for bold statements, these panels offer versatility and style. Advances in faux wood materials, like polystyrene and polyurethane, provide cost-effective, eco-friendly alternatives to traditional wood. Perfect for residential and commercial spaces, slat wall panels not only enhance aesthetics but also improve acoustics. Explore the full range of slat wall panel options.

Get Lead Lined Doors Delivered in Weeks, Not Months, with MarShield

May 6, 2025

Radiation shielding delays are a threat to compliance, safety, and operational timelines. Whether outfitting an imaging room or securing a nuclear facility, waiting 12 weeks for lead lined doors puts critical timelines and budgets in jeopardy. MarShield sets a new standard by averaging delivery of lead lined wood doors in 20 days and hollow metal lead doors in 30. That’s why decision makers are moving quickly to secure supply from a manufacturer who actually delivers.

Coco Architectural Grilles & Metalcraft: Butterfly Design for Merillon Avenue LIRR Station

May 1, 2025

Coco Architectural Grilles & Metalcraft, renowned for their custom metalwork, recently completed an intricate butterfly pattern design for the Merillon Avenue Long Island Rail Road (LIRR) station. This project highlights the company’s expertise in creating unique, high-quality metal designs for a variety of applications.

Sto Corp. Wins Project of the Year at EIFS Excellence Awards for Second Consecutive Year

April 29, 2025

Sto Corp., the innovative world leader in fully integrated facade systems, has been awarded the prestigious Project of the Year Award at the 2024 EIFS Excellence Awards for the second year in a row. This high-profile recognition underscore’s Sto Corp.’s leadership in energy efficiency, design versatility, and sustainable innovation across the building envelope industry.

Ballistic Wall Retrofitting: Enhancing Security with Armortex Solutions

April 24, 2025

Retrofitting a ballistic wall provides an effective solution for enhancing building security without the need for complete reconstruction. Whether the structure is a government building, school, corporate headquarters, or financial institution, reinforcing the walls can create vital protection against ballistic threats while keeping operations uninterrupted. This guide explores the process of retrofitting a standard wall into a reliable ballistic barrier, emphasizing the right materials and methods to match security requirements.