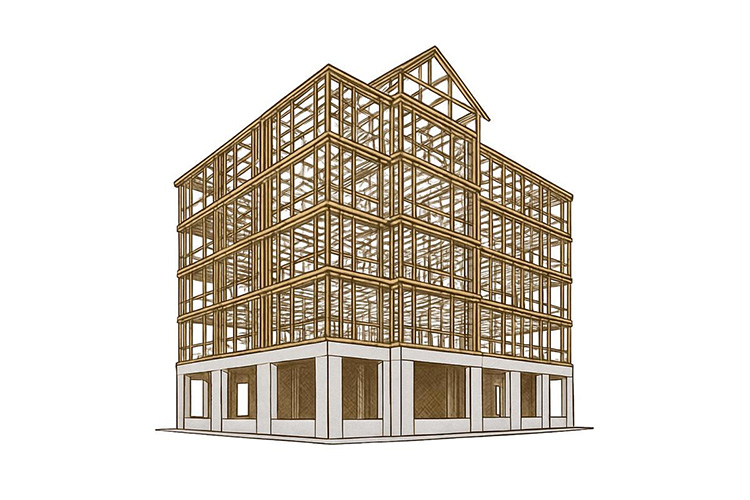

About Type V (Wood-Frame)

Type V (Wood-Frame)

Designed for residential and light commercial projects, EQUITONE panels can be face-fixed to wood substrates, with options that support both continuous insulation and non-CI assemblies.

EQUITONE panels can be face-fixed directly to wood framing systems, offering a durable and cost-effective rainscreen solution for Type V construction, such as low-rise residential, mixed-use, and light commercial buildings.

When designing rainscreen systems for Type V wood frame construction, understanding the difference between continuous insulation (CI) and non-CI assemblies is essential for meeting energy code requirements and performance goals.

CI systems incorporate a continuous layer of insulation—typically rigid foam, rigid mineral wool, or structurally insulated sheathing - installed on the exterior of the stud wall uninterrupted by framing members. EQUITONE panels are then mounted on vertical wood battens or furring strips, which sits outboard, or on the face of the insulation, maintaining a ventilated cavity between the cladding and insulation.

There are two types of non-CI systems. Either insulation is placed outboard of the exterior sheathing, between the wood battens or furring strips that EQUITONE is mounted to, or there is no exterior insulation used and all the insulation is between the structural studs behind the sheathing.

EQUITONE panels can be face-fixed to wood framing using stainless steel screws designed for long-term performance, visual consistency, and ease of installation in residential and light commercial projects.

The UNI-Wood Screw DP features a drill point tip that eliminates the need for predrilling, providing faster and more consistent installation on timber frames.

To ensure a durable and visually clean installation on Type V construction, follow these best practices when face fixing EQUITONE panels with UNI-Screw DP fasteners.

Type V (Wood-Frame) Construction

Face fixing to wood-frame construction

Continuous Insulation (CI) vs. Non-CI Assemblies

Continuous Insulation (CI)

Non-CI Assemblies

Fasteners

UNI-Wood Screw DP (Drill Point)

Design tips

Brochures | 3-Part CSI specifications | CAD details

03 40 00 - Precast Concrete

04 22 23 - Architectural Concrete Unit Masonry

04 22 23.13 - Exposed Aggregate Concrete Unit Masonry

04 22 23.16 - Fluted Concrete Unit Masonry

04 22 23.19 - Molded-Face Concrete Unit Masonry

04 22 23.23 - Prefaced Concrete Unit Masonry

04 22 23.26 - Sound-Absorbing Concrete Unit Masonry

04 22 23.29 - Split-Face Concrete Unit Masonry

04 42 00 - Exterior Stone Cladding

05 40 00 - Cold-Formed Metal Framing

06 10 00 - Rough Carpentry

07 21 00 - Thermal Insulation

07 27 00 - Air Barriers

07 27 13 - Modified Bituminous Sheet Air Barriers

07 27 16 - Sheet Metal Membrane Air Barriers

07 27 19 - Plastic Sheet Air Barriers

07 27 23 - Board Product Air Barriers

07 27 26 - Fluid-Applied Membrane Air Barriers

07 40 00 - Roofing and Siding Panels

07 42 13 - Metal Wall Panels

07 42 13.13 - Formed Metal Wall Panels

07 42 13.16 - Metal Plate Wall Panels

07 42 13.19 - Insulated Metal Wall Panels

07 42 13.23 - Metal Composite Material Wall Panels

07 42 43 - Composite Wall Panels

07 46 00 - Siding

07 46 46 - Fiber-Cement Siding

07 77 00 - Wall Specialties

07 84 00 - Firestopping