About Types I-IV (Commercial Building Code)

Types I-IV (Commercial Building Code)

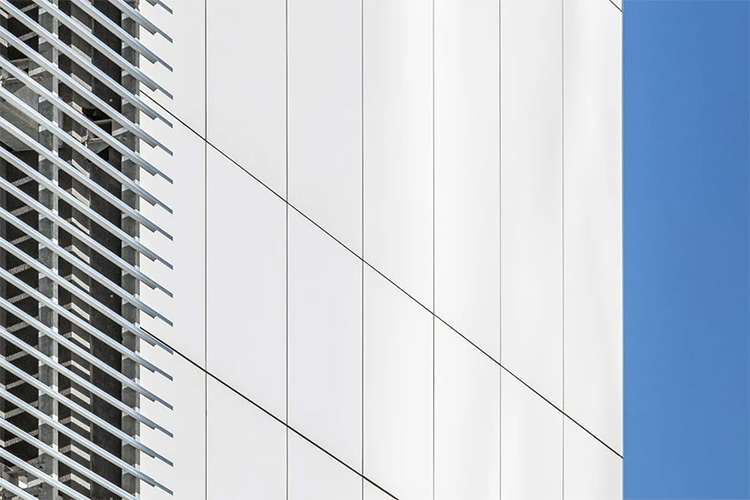

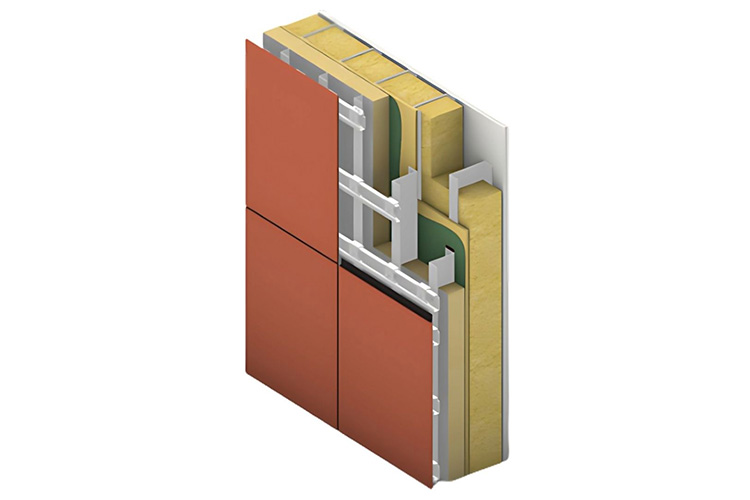

Noncombustible* exterior walls using metal subframing

Face fixing EQUITONE panels to metal subframing is a cost-effective attachment method and reliable solution for noncombustible construction. This method is widely used in mid-rise and high-rise projects for its simplicity, speed, and code compliance.

EQUITONE panels can be securely face-fixed to metal subframing using a variety of exposed fasteners. Choose the fastening solution that best meets your project’s structural and aesthetic needs.

Each fastening method is tested for long-term durability and integrates seamlessly into EQUITONE’s ventilated rainscreen design.

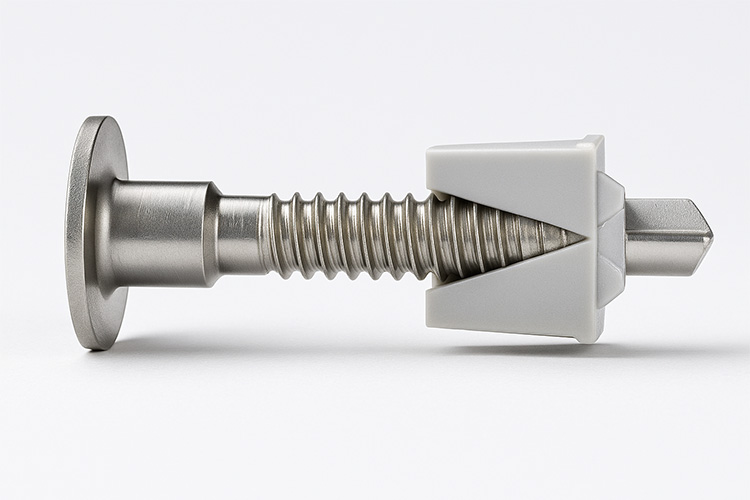

The EQUITONE UNI-Metal Screw can be used to affix 8 mm thick EQUITONE panels: EQUITONE [linea], EQUITONE [natura], EQUITONE [natura] PRO, EQUITONE [pictura], EQUITONE [tectiva] and EQUITONE [inspires] to a vertical façade, soffit or ceiling.

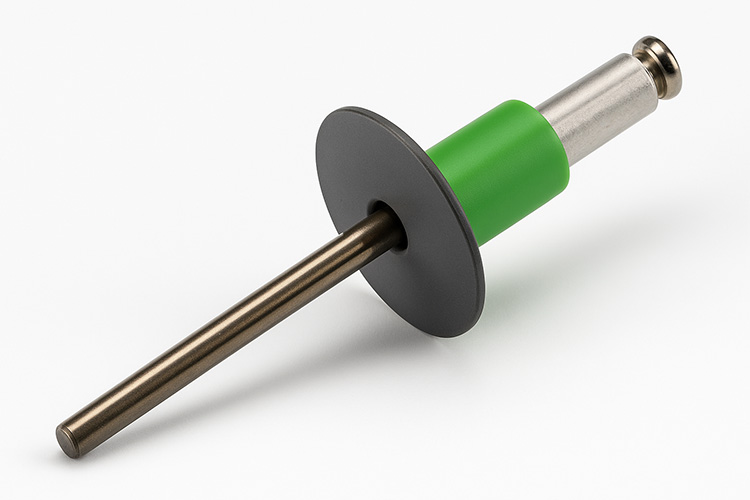

The EQUITONE UNI-Rivet can be used to fix EQUITONE's entire range of products and thickenesses to a vertical facade, soffit or ceiling.

When specifying face-fixed EQUITONE panels for Types I–IV construction, thoughtful detailing ensures performance, longevity, and visual appeal. Below are key design considerations:

Concealed fixing offers a clean, uninterrupted façade appearance while maintaining the durability and performance of EQUITONE fiber cement panels. This method is ideal for architects seeking a minimalist aesthetic without compromising on structural integrity.

EQUITONE panels can also be securely installed using concealed fixing methods, such as Tergo+ and TUF-S anchors.

The Tergo+ undercut anchor can be used to affix 8mm EQUITONE [tectiva], EQUITONE [linea], EQUITONE [lunara] and 12mm EQUITONE [natura], EQUITONE [natura] PRO, and EQUITONE [pictura].

The TUF-S blind fastener can be used to fix EQUITONE's entire range of products and thicknesses to a vertical facade, soffit, or ceiling.

Commercial Building Code - Types I-IV

Face fixing to metal

Fasteners

UNI-Metal Screw

UNI-Rivet

Design tips

Concealed fixed

Fasteners

Tergo+ Undercut Anchor

TUF-S Blind Fastener

Brochures | 3-Part CSI specifications | CAD details

03 40 00 - Precast Concrete

04 22 23 - Architectural Concrete Unit Masonry

04 22 23.13 - Exposed Aggregate Concrete Unit Masonry

04 22 23.16 - Fluted Concrete Unit Masonry

04 22 23.19 - Molded-Face Concrete Unit Masonry

04 22 23.23 - Prefaced Concrete Unit Masonry

04 22 23.26 - Sound-Absorbing Concrete Unit Masonry

04 22 23.29 - Split-Face Concrete Unit Masonry

04 42 00 - Exterior Stone Cladding

05 40 00 - Cold-Formed Metal Framing

06 10 00 - Rough Carpentry

07 21 00 - Thermal Insulation

07 27 00 - Air Barriers

07 27 13 - Modified Bituminous Sheet Air Barriers

07 27 16 - Sheet Metal Membrane Air Barriers

07 27 19 - Plastic Sheet Air Barriers

07 27 23 - Board Product Air Barriers

07 27 26 - Fluid-Applied Membrane Air Barriers

07 40 00 - Roofing and Siding Panels

07 42 13 - Metal Wall Panels

07 42 13.13 - Formed Metal Wall Panels

07 42 13.16 - Metal Plate Wall Panels

07 42 13.19 - Insulated Metal Wall Panels

07 42 13.23 - Metal Composite Material Wall Panels

07 42 43 - Composite Wall Panels

07 46 00 - Siding

07 46 46 - Fiber-Cement Siding

07 77 00 - Wall Specialties

07 84 00 - Firestopping