Sustainability

Rethinking the Building Envelope in a Changing Environment

February 18, 2026

As architectural performance standards continue to rise, building facades are evolving beyond static enclosures. Today’s projects increasingly demand envelopes that can adapt to environmental conditions, support occupant comfort, and contribute to long-term operational efficiency. One of the most progressive responses to these demands is the kinetic facade. Kinetic facade systems are designed to move or adjust in response to external stimuli such as daylight, airflow, or occupancy patterns. By introducing motion as a functional design element, these systems represent a convergence of architecture, engineering, and material innovation.

Draper Elevate: Advancing Cordless Manual Roller Shade Performance

February 13, 2026

Draper, Inc. has introduced Elevate, a next-generation cordless manual roller shade designed to meet growing demand for safer, smoother, and more refined manual shading systems in residential interiors. As interest in child-safe and visually clean window treatments continues to rise, Elevate offers a modern alternative to traditional manual shade technologies.

Elevating Interior Spaces with Vaulted Ceiling Design

February 11, 2026

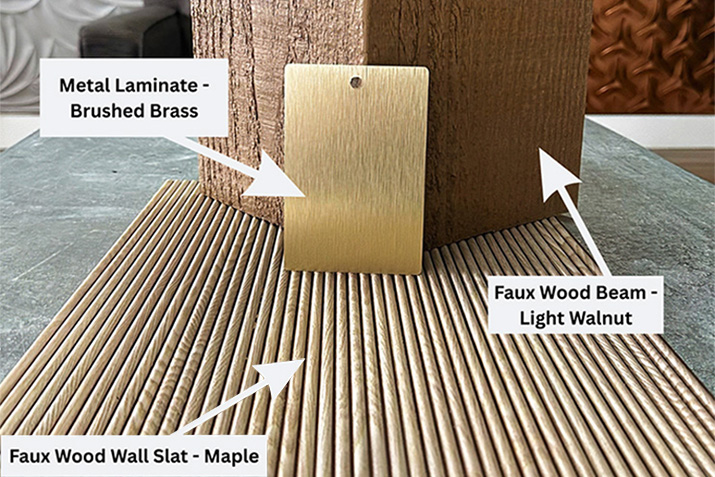

A vaulted ceiling is defined by its sloped, angled, or arched form, often following—though not strictly mirroring—the roofline. Unlike flat ceilings, vaulted designs create an immediate sense of height, openness, and architectural presence. As a result, they are frequently used in both residential and commercial interiors to enhance spatial experience and visual impact. When designed thoughtfully, vaulted ceilings become more than a structural feature—they serve as a central design element. The following design strategies highlight how faux wood beams, lighting, wall treatments, and finishes can be combined to maximize the aesthetic and functional potential of vaulted ceilings.

Tourlock 180 by Boon Edam: High-Security Revolving Door for High-Traffic Entrances

February 9, 2026

Controlling pedestrian access without compromising throughput has become a critical requirement for corporate headquarters, data centers, government buildings, and other high-risk facilities. Security revolving doors are increasingly specified for these environments due to their ability to combine access control with continuous traffic flow. The Tourlock 180 security revolving door from Boon Edam Inc. is designed to address this exact challenge, offering a robust entrance solution that supports high volumes of users while actively preventing unauthorized entry.

Kingspan Light + Air: Daylighting as a Strategic Investment in Building Value

January 23, 2026

In a competitive and economically uncertain real estate market, developers and building owners are increasingly focused on design strategies that enhance both occupant well-being and long-term asset performance. Daylighting has emerged as a proven approach that delivers measurable financial and operational benefits, while contributing to healthier indoor environments.

Sto Corp. Explores High-Performance Alternatives to Traditional Brick Design

December 24, 2025

Brick continues to shape architectural identity, but rising performance and sustainability demands are driving new design approaches. Sto Corp. explores how modern wall systems can replicate the look of brick while improving thermal efficiency, moisture control, and compliance with current energy codes. Read the full article.

Strategic Seasonal Planning with TerraCast®: Durable Resin Planters for Long-Term Performance

December 10, 2025

As property owners and facility teams prepare for the transition into a new season, winter presents an ideal window to evaluate outdoor environments, confirm material needs, and plan enhancements before demand surges in the spring. Taking advantage of this slower period allows specifiers, landscape professionals, and planners to secure high-performance products that will be ready for installation as soon as conditions improve.

Earth Shield® Waterstop Solutions by J P Specialties: Advanced Protection for Concrete Structures

November 21, 2025

Waterstops play a vital role in safeguarding concrete structures by preventing fluid migration through construction and expansion joints. As a long-established manufacturer in this field, J P Specialties, Inc. delivers a comprehensive portfolio of Earth Shield® waterstop products engineered for demanding applications across chemical processing, water and wastewater treatment, fuel handling, and environmental containment.

MarShield’s Plasti-Shield®: Advanced Borated Polyethylene for Reliable Neutron Shielding

November 12, 2025

Borated polyethylene has become a critical material for neutron shielding in both nuclear power and medical environments. Its effectiveness lies in its ability to moderate and absorb fast and thermal neutrons while remaining lightweight, durable, and cost-efficient—qualities that make it ideal for facilities requiring dependable radiation protection.

Terracast Resin Furnishings: Enhancing Public Spaces for the Fall Season

November 6, 2025

As autumn approaches, public spaces across cities and campuses transition to reflect the season’s atmosphere—shifting from summer’s vibrancy to fall’s warm and inviting tone. Parks, plazas, and community areas adapt to cooler weather, new events, and changing visitor patterns. Selecting the right outdoor furnishings becomes essential in ensuring these spaces remain both functional and welcoming. Terracast® resin furnishings offer a smart, sustainable solution designed to handle the unique challenges of seasonal change. Their combination of durability, weather resistance, and aesthetic versatility makes them an ideal choice for fall-ready environments.

Elite Crete Systems’ HERMETIC™ Flooring Delivers Superior Durability for Aircraft Hangars

October 27, 2025

Elite Crete Systems’ HERMETIC™ Aircraft Flooring Systems deliver long-lasting protection for aviation facilities. These high-build, resinous coatings resist Skydrol fluids, petrochemicals, and heavy impact—ideal for demanding hangar environments. Available in durable gloss or satin finishes, they combine strength, chemical resistance, and easy maintenance for modern aerospace operations.

TerraCast® Products Expands Millennium II Planter Line with Full Standard Color Selection

October 16, 2025

TerraCast® Products has expanded its popular Millennium II Series, providing designers and architects with greater creative flexibility. The Millennium II Rectangular and Millennium II Square planters are now available in the complete range of TerraCast’s standard colors, allowing for more cohesive and customized design applications.

Par-Kut International: Prefabricated Buildings Engineered to Endure

October 7, 2025

For more than seven decades, Par-Kut International has set the standard for durable, prefabricated structures. Established in 1954, the company continues to demonstrate that its products are truly built to last — a principle reflected in the long service life of Par-Kut buildings across the United States. Each structure is engineered and fabricated with meticulous attention to detail. From precise cutting and welding to protective coatings and finishes, every element is designed to withstand years of exposure to demanding environments. This focus on quality and resilience ensures that Par-Kut buildings remain functional and visually appealing long after installation.

PennBarry UVS Utility Vent Set: Reliable Ventilation for Commercial and Industrial Applications

September 30, 2025

Discover the PennBarry UVS Utility Vent Set, a durable and efficient housed centrifugal fan designed for commercial, institutional, and industrial HVAC applications.

Draper FlexShade ZIP with Solar Panels: Advancing Outdoor Comfort and Efficiency

September 25, 2025

Discover Draper FlexShade ZIP solar-powered shades—easy installation, smart control, and sustainable comfort for outdoor living spaces.

Avanti Systems USA: A Guide to Effective Acoustic Glass Partitions

September 12, 2025

In today’s workplaces, schools, medical facilities, and high-end residential projects, acoustics play a critical role in creating functional and comfortable environments. While glass partitions contribute to a sense of openness and light, they must also address the challenge of sound control. Selecting the right acoustic glass solution ensures both visual appeal and the performance needed to support productivity, privacy, and well-being. - Why Acoustic Performance Matters >

TerraCast® Rotomolded Planters: Durability and Design for Modern Landscapes

September 5, 2025

In contemporary landscape design, the performance of materials and the quality of construction are as critical as visual appeal. TerraCast® planters are crafted using rotational molding with LLDPE resin, creating a single, seamless unit. This one-piece design eliminates common weak points found in multi-part or assembled containers, enhancing durability, structural integrity, and long-term performance.

Decorative Ceiling Tiles Highlights Three Interior Design Trends

August 26, 2025

Interior design continues to evolve, blending timeless materials with modern innovations to create spaces that are both stylish and functional. Certain elements are experiencing renewed popularity, offering versatile solutions for residential and commercial interiors alike. DecorativeCeilingTiles.net identifies three standout trends that are shaping the design landscape in 2025.

Why Bullet-Resistant Materials Are Essential for Future-Proofing Your Designs

August 22, 2025

Ensuring that a building remains safe, durable, and functional over time requires careful consideration of the materials used in its construction. Incorporating bullet-resistant materials into building designs is an effective strategy for enhancing long-term security and resilience. These materials—ranging from ballistic steel to bullet-resistant glass and fiberglass—provide protection against firearms and other potential threats, contributing to a future-proofed design that prioritizes both safety and longevity.

13 Common Shower Wall Panel Challenges and How to Avoid Them

August 13, 2025

Mike Foti at Innovate Building Solutions offers some excellent insights into shower wall panels. We found his blog so helpful that we’ve summarized 13 key challenges and practical solutions to help you plan a stylish, trouble-free installation.