Safety

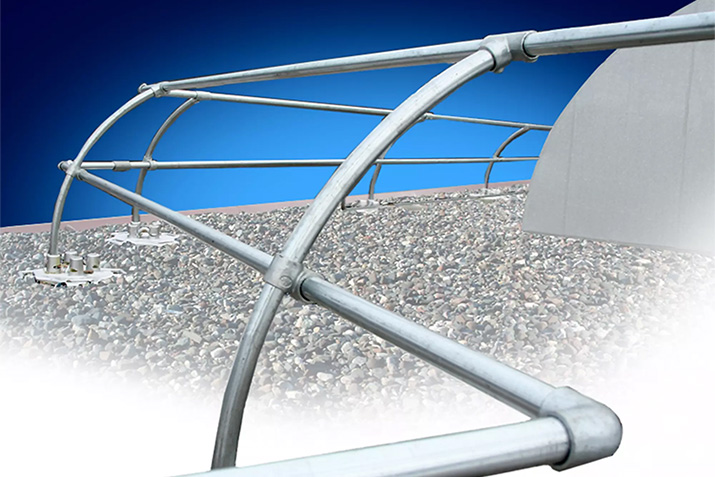

Enhancing Rooftop Safety Without Roof Penetration

February 27, 2026

Fall protection remains a critical priority for facility managers, safety professionals, and contractors working on commercial and industrial rooftops. On flat and low-slope roofs, traditional guardrail systems often require roof penetration, creating potential risks to waterproofing and long-term roof performance. Non-penetrating roof railing systems offer a practical alternative by delivering reliable fall protection without compromising the roof surface. Safety Rail Company provides engineered non-penetrating guardrail solutions designed to meet regulatory requirements while preserving roof integrity across a wide range of applications.

REFLECTOR™ Enhancer Flooring Systems for Architects

February 16, 2026

Elevate your architectural designs with the innovative REFLECTOR™ Enhancer Flooring System by Elite Crete Systems. Crafted exclusively for the discerning needs of commercial, industrial, and residential spaces, this specialty, high-build, self-leveling, and fluid-applied floor coating opens the door to a world of possibilities. When your project demands a flooring solution that seamlessly blends durability, longevity, aesthetics, ease of maintenance, and complete customization, the REFLECTOR™ system stands ready to meet and exceed your expectations. To ensure optimal results and capture the distinct essence of these flooring systems, we recommend engaging with our technical experts before installation or specification.

Draper Elevate: Advancing Cordless Manual Roller Shade Performance

February 13, 2026

Draper, Inc. has introduced Elevate, a next-generation cordless manual roller shade designed to meet growing demand for safer, smoother, and more refined manual shading systems in residential interiors. As interest in child-safe and visually clean window treatments continues to rise, Elevate offers a modern alternative to traditional manual shade technologies.

Roof Hatch Safety Reconsidered: LadderPort's Fixed Grab Bars as a Reliable Alternative to Telescoping Posts

January 28, 2026

Custom Radiation Shielding for Diagnostic Imaging

January 6, 2026

MarShield products are engineered for safety and compliance in X-ray, CT, MRI, and RF environments.

BILCO Access Solutions on Video: Safety and Performance in Practice

December 22, 2025

The BILCO Company continues to support architects, engineers, and building professionals with practical insights into safe and efficient building access. Through its dedicated YouTube channel, the company presents a broad collection of videos that demonstrate how its access solutions perform in real-world conditions. The video content focuses on both product functionality and application, offering clear explanations that help specifiers and facility managers make informed decisions. From installation guidance to operational benefits, the channel serves as a visual extension of BILCO’s technical expertise.

Bil-Guard® 2.0 Roof Hatch Safety Railing System

November 25, 2025

The Bil-Guard® 2.0 Roof Hatch Safety Railing System delivers permanent fall protection for roof hatch openings while exceeding OSHA regulations.

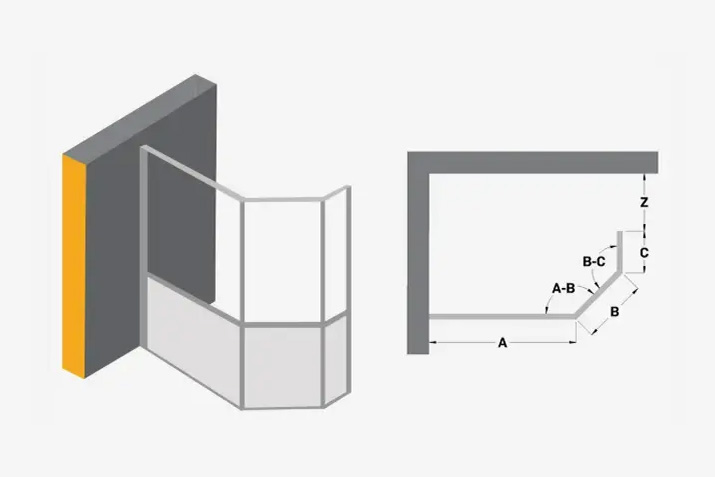

New Flange Mount Option For Model XP500 Aluminum Extreme Weather Louver

November 14, 2025

Ruskin is pleased to announce a new flange mounting option for the XP500 model. The XP500 is a stationary extreme weather louver with sight proof blades. This louver is tested to FEMA 361 standard design and ICC500 specification for large missile impact and can be mounted internally, externally or in conjunction with other louvers with a 5” deep frame.

MarShield’s Plasti-Shield®: Advanced Borated Polyethylene for Reliable Neutron Shielding

November 12, 2025

Borated polyethylene has become a critical material for neutron shielding in both nuclear power and medical environments. Its effectiveness lies in its ability to moderate and absorb fast and thermal neutrons while remaining lightweight, durable, and cost-efficient—qualities that make it ideal for facilities requiring dependable radiation protection.

Delivering Certified Lead Pours and Shielding Solutions for Nuclear Projects

October 31, 2025

MarShield has spent decades building shielding systems for nuclear facilities and research organizations across the world. Our focus in nuclear is clear. We support established plants, radioactive waste management sites, and advanced reactor projects, including small modular reactors (SMRs) and facilities using CANDU technology. Every product we deliver is reliable, certified, and supported with documentation. Our solutions are engineered to perform no matter the situation they are built for.

Elite Crete Systems’ HERMETIC™ Flooring Delivers Superior Durability for Aircraft Hangars

October 27, 2025

Elite Crete Systems’ HERMETIC™ Aircraft Flooring Systems deliver long-lasting protection for aviation facilities. These high-build, resinous coatings resist Skydrol fluids, petrochemicals, and heavy impact—ideal for demanding hangar environments. Available in durable gloss or satin finishes, they combine strength, chemical resistance, and easy maintenance for modern aerospace operations.

Total Security Solutions: Funding Paths for Hospital Security Upgrades

October 24, 2025

As hospitals adapt to new security challenges and potential changes to the Hospital Preparedness Program (HPP), healthcare leaders are exploring alternative ways to fund essential physical security improvements. Even without HPP support, multiple programs and grants can help finance upgrades such as bullet-resistant doors, secure entryways, and ballistic reception barriers.

Enhancing Workplace Safety with Safety Rail Company’s Modular Crossover Stairs

October 2, 2025

Safety Rail Company has redefined rooftop and facility access with its Modular Crossover Stairs. Designed for flexibility, compliance, and worker protection, this system delivers a safe and cost-effective way to overcome workplace obstacles.

Cranky™ Portable Winch System – A Smarter, Safer Way to Lift Heavy Loads

September 23, 2025

The Cranky Portable Winch System gives contractors, HVAC technicians, and facility managers a lightweight, collapsible way to lift up to 300 lbs. safely and efficiently—without cranes or extra labor. Weighing only 29 lbs., Cranky sets up quickly, works with multiple mounting posts, and includes OSHA-compliant safety features, making it a go-to alternative for safe rooftop and building access.

TerraCast® Rotomolded Planters: Durability and Design for Modern Landscapes

September 5, 2025

In contemporary landscape design, the performance of materials and the quality of construction are as critical as visual appeal. TerraCast® planters are crafted using rotational molding with LLDPE resin, creating a single, seamless unit. This one-piece design eliminates common weak points found in multi-part or assembled containers, enhancing durability, structural integrity, and long-term performance.

MarShield Named Official Canadians for CANDU Ambassador

September 3, 2025

As regulatory scrutiny tightens and radiation shielding demands evolve, Canada’s nuclear sector needs more than off-the-shelf solutions. It needs precision, partnership, and proven performance. That’s why MarShield’s recognition as an official ambassador for the Canadians for CANDU campaign marks a critical milestone for the future of radiation protection and Canadian-engineered nuclear solutions.

Ultraray Launches Modular Control Booth Builder for Precision Real-Time Design

August 28, 2025

Ultraray has introduced its new Modular Control Booth Builder, an online platform that enables users to design, customize, and visualize control booths in real time. This tool streamlines the design process, enhancing accuracy and reducing the risk of costly errors.

LadderPort™ Ladder Receiver: Enhancing Technician Safety and Protecting Buildings

August 15, 2025

Rooftop access remains one of the most hazardous aspects of maintenance and repair work. Each year, thousands of workplace injuries are attributed to unstable ladder setups, awkward transitions, and preventable accidents. According to the CDC, ladder-related incidents accounted for over 22,000 workplace injuries in 2020, with maintenance and repair sectors particularly affected. These statistics highlight the need for safer rooftop access solutions that reduce both risk and liability.

BlueWater Architectural Series Roof Guardrail System

July 30, 2025

Discover the BlueWater Architectural Series, seamlessly combining OSHA-compliant non-penetrating guardrails with elegant architectural design. Ideal for maintaining roof integrity without compromising aesthetics. Available in Straight and Incline Stanchions for versatile applications. Enhance safety with style.

New mobile full-height turnstile specifically designed for dynamic and demanding temporary deployments

June 24, 2025

Boon Edam Inc., a global leader in physical security entrance products, introduces the Turnlock 100 Mobile Platform, a new mobile security solution combining the proven performance of a Boon Edam full-height turnstile with a heavy-duty, forklift-ready base for easy transportation and deployment. Designed to be moved and redeployed as site conditions evolve, this portable security solution provides a fast, effective way to secure construction jobsites or temporary venues with the highest levels of durability, strength and safety while maintaining compliance.