Building

Innovate Building Solutions Bathroom Visualizer Simplifies Bathroom Design Decisions

March 4, 2026

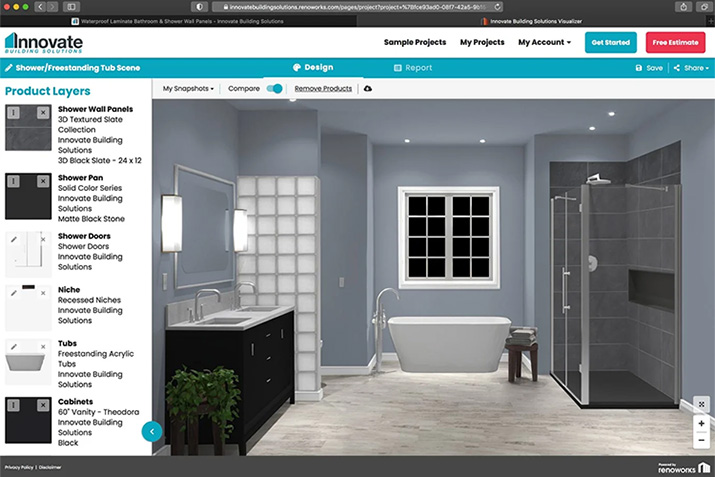

Planning a bathroom renovation often involves balancing aesthetics, functionality, and product compatibility. To support homeowners, designers, and remodelers during the early decision-making phase, Innovate Building Solutions offers an interactive Bathroom Visualizer that transforms ideas into clear, realistic design concepts. The online visualizer allows users to explore a wide range of bathroom configurations before committing to specific products. By combining finishes, materials, and layouts digitally, design choices can be evaluated efficiently and with greater confidence.

Removable Ballistic Glazing for Temporary Executive Protection in a Historic Hotel

February 20, 2026

When a high-ranking foreign official required discreet, rifle-rated protection during a short stay in a historic Washington, D.C. hotel, the security solution needed to meet strict requirements. The suite could not be permanently altered in any way, yet the identified threat level demanded enhanced ballistic protection across multiple window openings. This challenge called for a temporary, non-invasive system that could be installed and removed quickly, without compromising the building’s historic finishes or daily operations.

Rethinking the Building Envelope in a Changing Environment

February 18, 2026

As architectural performance standards continue to rise, building facades are evolving beyond static enclosures. Today’s projects increasingly demand envelopes that can adapt to environmental conditions, support occupant comfort, and contribute to long-term operational efficiency. One of the most progressive responses to these demands is the kinetic facade. Kinetic facade systems are designed to move or adjust in response to external stimuli such as daylight, airflow, or occupancy patterns. By introducing motion as a functional design element, these systems represent a convergence of architecture, engineering, and material innovation.

Draper Elevate: Advancing Cordless Manual Roller Shade Performance

February 13, 2026

Draper, Inc. has introduced Elevate, a next-generation cordless manual roller shade designed to meet growing demand for safer, smoother, and more refined manual shading systems in residential interiors. As interest in child-safe and visually clean window treatments continues to rise, Elevate offers a modern alternative to traditional manual shade technologies.

Elevating Interior Spaces with Vaulted Ceiling Design

February 11, 2026

A vaulted ceiling is defined by its sloped, angled, or arched form, often following—though not strictly mirroring—the roofline. Unlike flat ceilings, vaulted designs create an immediate sense of height, openness, and architectural presence. As a result, they are frequently used in both residential and commercial interiors to enhance spatial experience and visual impact. When designed thoughtfully, vaulted ceilings become more than a structural feature—they serve as a central design element. The following design strategies highlight how faux wood beams, lighting, wall treatments, and finishes can be combined to maximize the aesthetic and functional potential of vaulted ceilings.

Tourlock 180 by Boon Edam: High-Security Revolving Door for High-Traffic Entrances

February 9, 2026

Controlling pedestrian access without compromising throughput has become a critical requirement for corporate headquarters, data centers, government buildings, and other high-risk facilities. Security revolving doors are increasingly specified for these environments due to their ability to combine access control with continuous traffic flow. The Tourlock 180 security revolving door from Boon Edam Inc. is designed to address this exact challenge, offering a robust entrance solution that supports high volumes of users while actively preventing unauthorized entry.

Understanding Low-Spall Bulletproof Glass

February 6, 2026

Bullet-resistant glass is often expected to provide complete protection once a projectile is stopped. However, real-world ballistic events demonstrate that stopping penetration alone does not guarantee occupant safety. In many cases, the interior surface of conventional ballistic glass fractures on impact, releasing sharp fragments into the protected space. Low-spall bulletproof glass addresses this critical safety gap by controlling how the glass behaves after impact, significantly reducing the release of hazardous debris.

Flexible Modular Construction for Larger, Customized Buildings

February 4, 2026

Par-Kut International, Inc. specializes in the design and manufacture of prefabricated buildings and enclosures for security, access control, and industrial environments. While many Par-Kut structures are delivered as single, fully assembled units, larger or more customized projects often benefit from a multi-section modular approach. As facility requirements continue to grow in size and complexity, modular construction has become an increasingly practical solution for applications such as security buildings, gate houses, and in-plant offices. By dividing a structure into multiple sections, larger footprints and more intricate layouts can be achieved while maintaining the efficiency of off-site fabrication.

Kingspan Light + Air: Daylighting as a Strategic Investment in Building Value

January 23, 2026

In a competitive and economically uncertain real estate market, developers and building owners are increasingly focused on design strategies that enhance both occupant well-being and long-term asset performance. Daylighting has emerged as a proven approach that delivers measurable financial and operational benefits, while contributing to healthier indoor environments.

Sto Corp. Explores High-Performance Alternatives to Traditional Brick Design

December 24, 2025

Brick continues to shape architectural identity, but rising performance and sustainability demands are driving new design approaches. Sto Corp. explores how modern wall systems can replicate the look of brick while improving thermal efficiency, moisture control, and compliance with current energy codes. Read the full article.

Florence Corporation and the Value of Authorized Local Dealers in Centralized Mailbox Projects

December 19, 2025

Since 1934, Florence Corporation has played a leading role in the development of centralized mail delivery equipment. A key part of this long-standing success is Florence’s nationwide network of Authorized Dealers, providing localized expertise and support across all 50 U.S. states. Rather than relying solely on remote sales channels, Florence works closely with specialized local partners who understand regional requirements, postal regulations, and on-site conditions. This approach ensures that mailbox solutions are not only compliant but also practical and efficiently implemented.

Evaluating Click-Together vs. Full-Sheet Shower Wall Panels: Key Considerations for Today’s Bathroom Projects

December 8, 2025

As the market for grout-free shower wall systems continues to expand, design professionals, contractors, and homeowners face an increasing number of material and installation options. Two of the most common solutions—click-together shower wall panels and full-sheet wall panels—each offer distinct advantages and limitations. Understanding these differences is essential for selecting a system that supports project goals related to performance, aesthetics, installation, and long-term maintenance. This overview examines the primary benefits and drawbacks of both panel categories, providing a practical comparison to support informed decision-making in residential and commercial bathroom renovations.

Par-Kut Ground Crew Shelters Enhance Airside Safety and Operations

December 3, 2025

Airports rely on a wide network of personnel to maintain smooth and secure operations, and ground crews form one of the most critical links in that chain. To support these demanding roles, many airport operators are turning to durable, prefabricated steel shelters from Par-Kut International, Inc. These structures provide a dependable solution for crew protection, coordination, and overall efficiency on the airside.

Earth Shield® Waterstop Solutions by J P Specialties: Advanced Protection for Concrete Structures

November 21, 2025

Waterstops play a vital role in safeguarding concrete structures by preventing fluid migration through construction and expansion joints. As a long-established manufacturer in this field, J P Specialties, Inc. delivers a comprehensive portfolio of Earth Shield® waterstop products engineered for demanding applications across chemical processing, water and wastewater treatment, fuel handling, and environmental containment.

MarShield’s Plasti-Shield®: Advanced Borated Polyethylene for Reliable Neutron Shielding

November 12, 2025

Borated polyethylene has become a critical material for neutron shielding in both nuclear power and medical environments. Its effectiveness lies in its ability to moderate and absorb fast and thermal neutrons while remaining lightweight, durable, and cost-efficient—qualities that make it ideal for facilities requiring dependable radiation protection.

Boon Edam Speedlane Compact Optical Turnstile Platform

October 14, 2025

Transform Your Entryways Without Disruption - Boon Edam introduces the Speedlane Compact Platform—a modular, non-invasive solution for modern access control. Perfect for historic landmarks and new facilities alike, it combines ADA-compliant design, high stability, and sleek finishes to fit any space. Discover how this innovative platform is setting a new standard for secure, seamless entrances.

Titus NEXUS OR Suite: Integrated Airflow and Lighting Solutions for Modern Operating Rooms

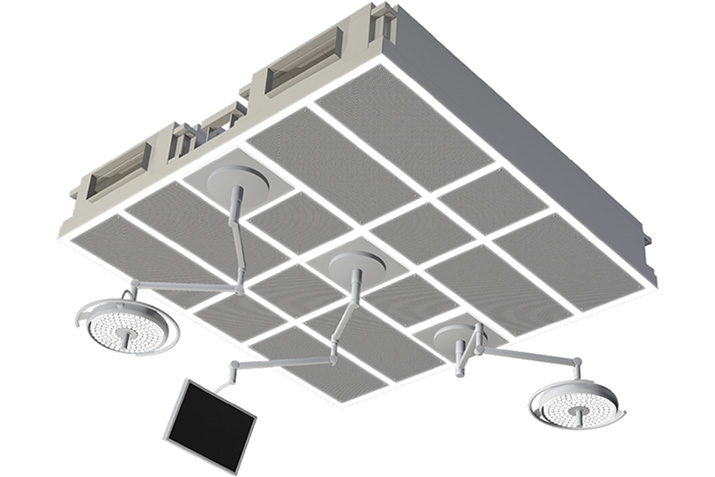

October 9, 2025

Titus has developed the NEXUS OR Suite to address the growing need for efficient, hygienic, and space-optimized airflow systems in healthcare environments. This integrated solution unites air distribution, lighting, and structural functionality to enhance both air quality and operational efficiency within surgical suites.

The NEXUS OR Suite employs a shared, low-profile plenum design that simplifies installation in both new construction and retrofit projects. Its modular configuration ensures quick setup with minimal disruption to adjacent areas, making it particularly suited for healthcare facilities requiring precise ventilation performance and streamlined ceiling integration.

Par-Kut International: Prefabricated Buildings Engineered to Endure

October 7, 2025

For more than seven decades, Par-Kut International has set the standard for durable, prefabricated structures. Established in 1954, the company continues to demonstrate that its products are truly built to last — a principle reflected in the long service life of Par-Kut buildings across the United States. Each structure is engineered and fabricated with meticulous attention to detail. From precise cutting and welding to protective coatings and finishes, every element is designed to withstand years of exposure to demanding environments. This focus on quality and resilience ensures that Par-Kut buildings remain functional and visually appealing long after installation.

Enhancing Workplace Safety with Safety Rail Company’s Modular Crossover Stairs

October 2, 2025

Safety Rail Company has redefined rooftop and facility access with its Modular Crossover Stairs. Designed for flexibility, compliance, and worker protection, this system delivers a safe and cost-effective way to overcome workplace obstacles.

PennBarry UVS Utility Vent Set: Reliable Ventilation for Commercial and Industrial Applications

September 30, 2025

Discover the PennBarry UVS Utility Vent Set, a durable and efficient housed centrifugal fan designed for commercial, institutional, and industrial HVAC applications.