Concrete

REFLECTOR™ Enhancer Flooring Systems for Architects

February 16, 2026

Elevate your architectural designs with the innovative REFLECTOR™ Enhancer Flooring System by Elite Crete Systems. Crafted exclusively for the discerning needs of commercial, industrial, and residential spaces, this specialty, high-build, self-leveling, and fluid-applied floor coating opens the door to a world of possibilities. When your project demands a flooring solution that seamlessly blends durability, longevity, aesthetics, ease of maintenance, and complete customization, the REFLECTOR™ system stands ready to meet and exceed your expectations. To ensure optimal results and capture the distinct essence of these flooring systems, we recommend engaging with our technical experts before installation or specification.

Earth Shield® Waterstop Solutions by J P Specialties: Advanced Protection for Concrete Structures

November 21, 2025

Waterstops play a vital role in safeguarding concrete structures by preventing fluid migration through construction and expansion joints. As a long-established manufacturer in this field, J P Specialties, Inc. delivers a comprehensive portfolio of Earth Shield® waterstop products engineered for demanding applications across chemical processing, water and wastewater treatment, fuel handling, and environmental containment.

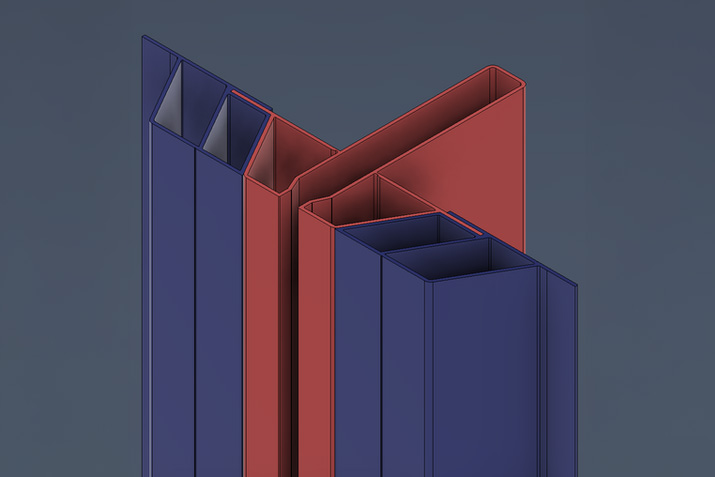

Keycup® Waterstop: Revolutionizing Concrete Joint Formation

September 15, 2025

Keycup® is a groundbreaking, multi-functional concrete accessory engineered to simplify and enhance construction joint formation. Keycup® was recently named “Most Innovative Concrete Accessory” at the 2024 World of Concrete in Las Vegas, NV, underscoring its industry-changing impact.

Add Direct Basement Access Quickly and Economically with PermEntry®

August 4, 2025

Consisting of a precast concrete stairwell and a BILCO basement door, a PermEntry basement entrance is the fastest and most economical way to add convenient, direct basement access to any home. PermEntry® is ideal for new home construction and can be delivered and installed by a BILCO PermEntry® dealer in just a few hours.

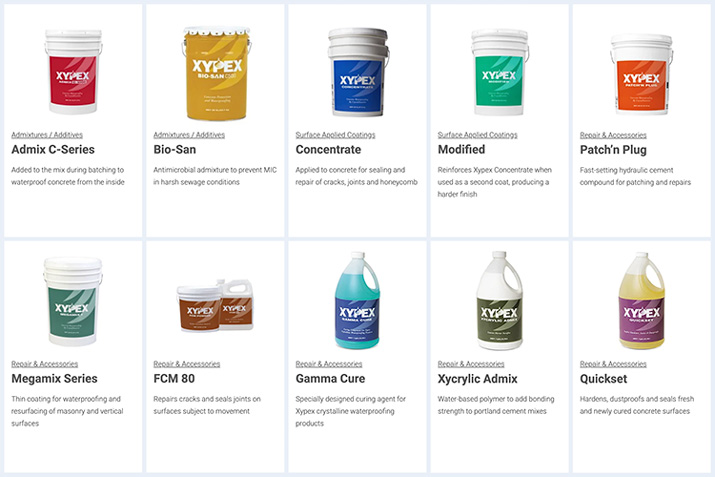

Xypex Concrete Waterproofing Products

May 30, 2025

Whether used as admixtures and added directly to cast-in-place concrete, shotcrete and precast concrete, or as surface-applied coatings, Xypex Crystalline Technology products are recognized for their versatility in solving concrete waterproofing challenges. Proven in thousands of applications in diverse construction projects and environments, Xypex products are specified and requested throughout the construction industry by engineers, architects and contractors for the permanent protection of all types of concrete.

Design with Freedom – Custom Terrazzo Solutions by Wausau Tile

April 17, 2025

Wausau Tile’s terrazzo offers unparalleled design flexibility, providing a wide range of custom colors, patterns, and even lettering. Whether using cement or epoxy, the possibilities are endless. If you can dream it, Wausau Tile can create it, offering a premium terrazzo solution for projects of all sizes.

Evaluating the Efficacy and Sustainability of Xypex Crystalline Waterproofing in Concrete

March 27, 2025

Concrete is essential to modern infrastructure but faces challenges due to its porous nature and susceptibility to cracking. This can lead to water ingress, reinforcing-steel corrosion and decreased structural lifespan. This article examines the Xypex Crystalline Waterproofing exclusive and proprietary technology, focusing on its technical performance, environmental sustainability and economic viability.

The Role of High-Density Concrete Blocks in Medical Radiation Facilities

November 5, 2024

High-density concrete blocks are integral to the construction of radiation therapy rooms, providing essential shielding for healthcare workers, patients, and the medical environment. For construction professionals working on projects in hospitals and cancer treatment centers, these blocks are critical in ensuring compliance with safety regulations and protecting against radiation exposure. With MarShield’s high-density concrete blocks, you can achieve superior radiation shielding while optimizing the construction process, cutting down on time and labor costs.

Elite Crete Systems Specialty Flooring for Breweries, Wineries and Distilleries

October 9, 2024

The brewing, winemaking and distillery industries face unique challenges when it comes to flooring. Our flooring systems are thermal shock resistant to withstand forced steam and boiling water cleaning methods. These surfaces are slip resistant and offer chemical and stain resistance to common industrial cleaners and sterilizers. They offer a variety of options to meet the individual needs of your facility while being FDA, USDA and CFIA acceptable.

PENETRON ADMIX Ensures Impermeable Concrete For Miami’s Modera Riverside Tower

August 8, 2024

Welcoming its first residents in August 2024, the Modera Riverside tower in Miami, Florida, is the newest highlight of the Miami skyline. The project engineer specified PENETRON ADMIX SB, a crystalline waterproofing admixture, to protect key below-grade concrete structures from Florida’s high groundwater and tropical climate.

Commercial Pool Decks & Waterparks

June 26, 2024

Discover durable and aesthetically appealing flooring solutions for commercial pool decks and waterparks with Elite Crete Systems. Elite Crete Systems specialty coatings are engineered to enhance safety and longevity, ideal for both indoor and outdoor environments.

Precast Terrazzo: Merging Tradition with Modern Innovation for Unmatched Uniformity

June 3, 2024

Precast terrazzo: the elegance and everlasting beauty is indisputable. Wausau Tile's custom precast terrazzo surfaces are sought after for everything from floors to countertops and wall treatments and stairs.

Maxxon® Gyp-Crete® High Performance: Revolutionizing Flooring Underlayment

April 26, 2024

AECinfo.com is thrilled to spotlight Maxxon® Gyp-Crete® High Performance, a groundbreaking solution revolutionizing modern flooring underlayment. Designed to meet the rigorous demands of contemporary floor coverings, including LVT, Gyp-Crete® High Performance stands as the strongest match for today's flooring needs.

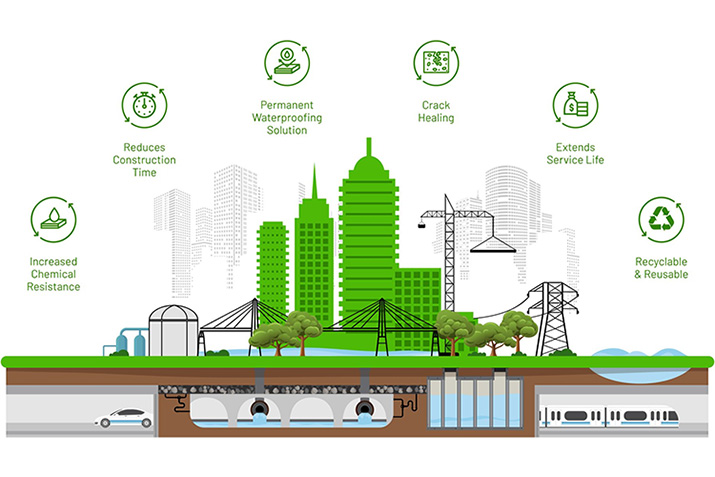

Unlock Sustainable Construction with Xypex Waterproofing Technology: Embrace Sustainability in Every Pour

March 25, 2024

Sustainability isn't just a concept; it's ingrained in Xypex's DNA. With over five decades of dedication, Xypex crystalline technology redefines waterproofing, integrating durability, longevity, and environmental consciousness into every project.

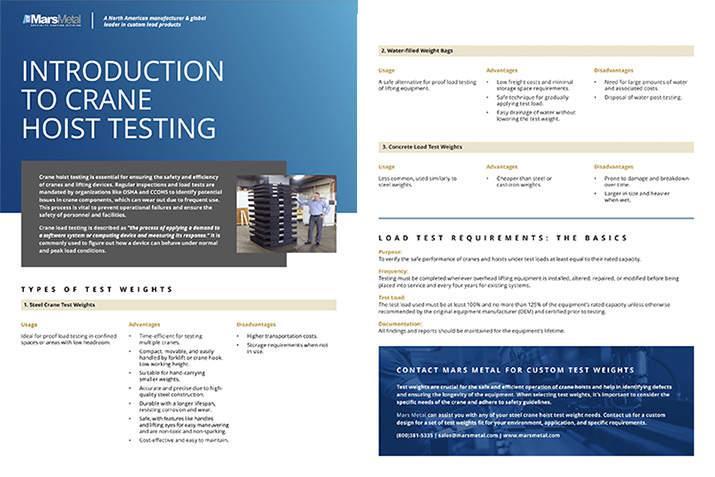

Mars Metal's Introduction to Crane Hoist Testing

November 27, 2023

A recent addition to the MarsMetal site explores the vital importance of crane hoist testing, focusing on ensuring safety and efficiency in crane operations. The resource discusses various test weight types, their pros and cons, load test requirements, and the significance of proper weight selection. It emphasizes Mars Metal's capability to craft tailor-made test weights, reflecting the company's commitment to crane safety and operational excellence. The new resource enriches the understanding of crane hoist testing and showcases MarsMetal's expertise in this field.

Specialty floors for food & beverage environments withstand high temperatures and forced steam cleaning

October 19, 2023

See HERMETIC™ 4.8S Urethane Cement, here installed in a commercial kitchen. These specialty floors by Elite Crete Systems were engineered specifically for food & beverage environments and withstand high temperatures including forced steam cleaning.

Introducing the REFLECTOR™ Enhancer Flooring Systems for Architects

August 25, 2023

Elevate your architectural designs with the innovative REFLECTOR™ Enhancer Flooring System by Elite Crete Systems. Crafted exclusively for the discerning needs of commercial, industrial, and residential spaces, this specialty, high-build, self-leveling, and fluid-applied floor coating opens the door to a world of possibilities. When your project demands a flooring solution that seamlessly blends durability, longevity, aesthetics, ease of maintenance, and complete customization, the REFLECTOR™ system stands ready to meet and exceed your expectations. To ensure optimal results and capture the distinct essence of these flooring systems, we recommend engaging with our technical experts before installation or specification.

Introducing Stromberg GFRC: The Future of Reinforced Concrete

August 10, 2023

Traditional concrete has long been fortified with steel to enhance its strength, but a revolutionary evolution has occurred with the advent of Glass Fiber Reinforced Concrete (GFRC). GFRC takes concrete to a new level, harnessing the power of glass fibers for reinforcement instead of steel. This groundbreaking innovation has redefined the possibilities of construction materials and techniques.

Sydney Metro’s Central Walk Relies On Penetron Technology For Durability

August 1, 2023

The Sydney Metro Central Walk, the latest construction phase of the Sydney Metro City & Southwest project, was opened to the public by the New South Wales government (Australia) in April 2023. The underground pedestrian tunnel used the Penetron System, a comprehensive crystalline waterproofing system, to protect the below-grade concrete tunnel structures from high hydrostatic pressure.

3 Retail Flooring Options

May 30, 2023

Retail clients can offer some of the best opportunities for flooring contractors. These projects typically involve significant square footage, generous budgets, and the potential for follow-up projects—during a shopping mall renovation or location expansion, for example. But what are the best retail flooring options to propose to a client? Here we look at three versatile retail flooring options suitable for locations like department stores, grocery stores, clothing stores, bookstores, and convenience stores.