Wall Panels

Elevating Interior Spaces with Vaulted Ceiling Design

February 11, 2026

A vaulted ceiling is defined by its sloped, angled, or arched form, often following—though not strictly mirroring—the roofline. Unlike flat ceilings, vaulted designs create an immediate sense of height, openness, and architectural presence. As a result, they are frequently used in both residential and commercial interiors to enhance spatial experience and visual impact. When designed thoughtfully, vaulted ceilings become more than a structural feature—they serve as a central design element. The following design strategies highlight how faux wood beams, lighting, wall treatments, and finishes can be combined to maximize the aesthetic and functional potential of vaulted ceilings.

Kingspan Light + Air: Daylighting as a Strategic Investment in Building Value

January 23, 2026

In a competitive and economically uncertain real estate market, developers and building owners are increasingly focused on design strategies that enhance both occupant well-being and long-term asset performance. Daylighting has emerged as a proven approach that delivers measurable financial and operational benefits, while contributing to healthier indoor environments.

Evaluating Click-Together vs. Full-Sheet Shower Wall Panels: Key Considerations for Today’s Bathroom Projects

December 8, 2025

As the market for grout-free shower wall systems continues to expand, design professionals, contractors, and homeowners face an increasing number of material and installation options. Two of the most common solutions—click-together shower wall panels and full-sheet wall panels—each offer distinct advantages and limitations. Understanding these differences is essential for selecting a system that supports project goals related to performance, aesthetics, installation, and long-term maintenance. This overview examines the primary benefits and drawbacks of both panel categories, providing a practical comparison to support informed decision-making in residential and commercial bathroom renovations.

Draper LED Mounts and Structures: Precision, Flexibility, and Complete Support for Video Wall Installations

November 4, 2025

When planning an LED video wall, selecting the display is just the beginning. The mounting structure is what ensures the installation performs flawlessly — both visually and structurally. Draper, Inc. designs LED mounting solutions that combine precision engineering, flexible installation options, and long-term reliability, addressing challenges that standard or OEM mounts often overlook.

Avanti Systems USA: A Guide to Effective Acoustic Glass Partitions

September 12, 2025

In today’s workplaces, schools, medical facilities, and high-end residential projects, acoustics play a critical role in creating functional and comfortable environments. While glass partitions contribute to a sense of openness and light, they must also address the challenge of sound control. Selecting the right acoustic glass solution ensures both visual appeal and the performance needed to support productivity, privacy, and well-being. - Why Acoustic Performance Matters >

Decorative Ceiling Tiles Highlights Three Interior Design Trends

August 26, 2025

Interior design continues to evolve, blending timeless materials with modern innovations to create spaces that are both stylish and functional. Certain elements are experiencing renewed popularity, offering versatile solutions for residential and commercial interiors alike. DecorativeCeilingTiles.net identifies three standout trends that are shaping the design landscape in 2025.

13 Common Shower Wall Panel Challenges and How to Avoid Them

August 13, 2025

Mike Foti at Innovate Building Solutions offers some excellent insights into shower wall panels. We found his blog so helpful that we’ve summarized 13 key challenges and practical solutions to help you plan a stylish, trouble-free installation.

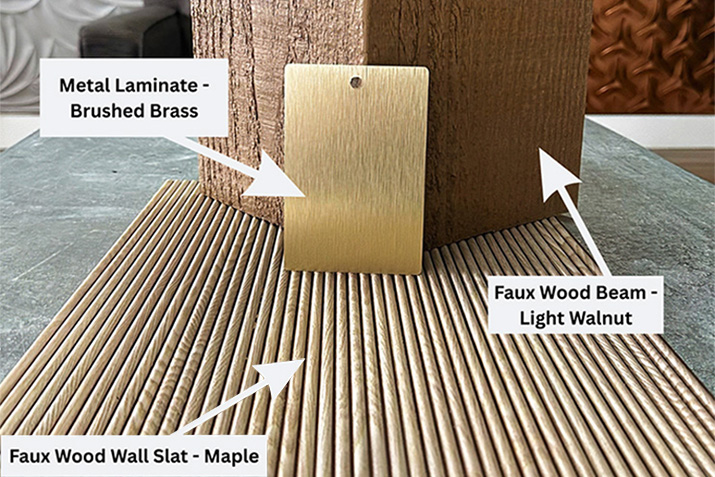

How to Choose Slat Wall Panels for Your Room Upgrade

May 13, 2025

Slat wall panels, inspired by traditional Japanese design, have become a timeless feature in modern interiors. With a variety of sizes and materials, from mini slats for minimalist spaces to large slats for bold statements, these panels offer versatility and style. Advances in faux wood materials, like polystyrene and polyurethane, provide cost-effective, eco-friendly alternatives to traditional wood. Perfect for residential and commercial spaces, slat wall panels not only enhance aesthetics but also improve acoustics. Explore the full range of slat wall panel options.

Innovate Building Solutions: The Advantages of Laminate Shower and Bathroom Wall Panels for Multi-Unit Housing

February 26, 2025

When it comes to maintaining and upgrading bathrooms in multi-unit properties, property managers face a unique set of challenges. From hotels and multi-family apartments to senior housing and student dormitories, the need for durable, low-maintenance, and aesthetically pleasing bathroom solutions is paramount. Innovate Building Solutions offers a revolutionary approach with their laminate shower and bathroom wall panels, providing an alternative to traditional ceramic tiles and other materials.

Exploring StoneLite®: Versatile Applications in Exterior Stone Design

February 21, 2025

StoneLite® panels have over four decades of proven performance on the exterior of buildings throughout the world. After many years of exposure to many different environments and being subjected to extreme heat, bitter cold, earthquakes and hurricanes, the panels not only retain their natural beauty but remain durable and continue to perform.

The StoneLite® exterior stone paneling system and its installation components have been thoroughly tested by leading independent testing laboratories. They have proven performance in bond strength and flexural strength following acid freeze/thaw and UV radiation exposure. They are accepted by I.C.C. (formerly ICBO) and other code bodies for unrestricted use as exterior cladding for Type I buildings.

How to Improve Room Acoustics and Reduce Noise

February 11, 2025

Have you ever walked into a room and immediately noticed the echo with harsh sounds reflecting off the walls and felt overwhelmed by the noise? A noisy room is something that we’ve learned to accept. It could be a large open room that echoes or an open-plan living space and kitchen where you can’t have a conversation or watch TV when someone else is cooking and vice-versa. Maybe your home office is in between the kids rooms or borders the neighbors' apartment that’s housed by an aspiring singer and the sound penetrates through the walls.

Dual Glazed LiteSpace: Enhanced Acoustic Privacy Meets Modern Design for Interior Spaces

December 16, 2024

Special-Lite®, a leader in architectural solutions for more than 50 years, is proud to announce the launch of the Dual Glazed LiteSpace system—a sophisticated and high-performance solution for modern interior environments where sound insulation and aesthetic appeal are high priorities.

StonePly Stone Panels: The Ultimate Solution for Modern Stone Cladding

December 6, 2024

StonePly stone panels revolutionize traditional stone cladding with their unique blend of natural beauty, strength, and advanced engineering. Whether you’re designing a skyscraper or a boutique interior, StonePly offers unmatched benefits.

Morin Matrix Series™: Versatile Rainscreen & Wall Panel Solutions

November 20, 2024

The Morin Matrix Series™ is a concealed fastener rainscreen/wall panel system. It features ten different profiles with unique bold box rib configurations. Combine with other Matrix panels, or with panels from our Integrity Series or Pulse Series.

National Gypsum Introduces Innovative MaX 16® Fastener Pattern

September 11, 2024

RSMeans data from Gordian time/motion study shows the new 16” o.c. optimized fastener pattern will deliver significant labor and material savings for commercial drywall installation.

Shower Wall Panel Patterns: Maximalist, Transitionalist, and Scandinavian Designs

May 21, 2024

The perception that shower wall panels are synonymous with plain, white, and institutional designs is outdated. While basic white glossy panels are still available and cost-effective, today's options offer style without compromising on ease of maintenance. This is great news for those looking to avoid the hassle of grout joints while enhancing their bathroom aesthetics.

Revolutionizing Architectural Design: The Superiority of StoneLite® Panels

May 7, 2024

In the ever-evolving realm of architectural design, the fusion of innovation and tradition is paramount. Among the myriad materials available to architects, one name stands out for its unparalleled versatility, durability, and aesthetic appeal: StoneLite®. The recent renovation and expansion of the iconic Philadelphia Museum of Art, designed by the visionary Frank Gehry, serves as a compelling showcase of the transformative power of StoneLite® panels. Amidst the architectural splendor of Gehry's creation, Stone Panels International LLC (SPI) seamlessly integrated StoneLite® Glacier Buff limestone into various facets of the museum's interior, elevating both form and function.

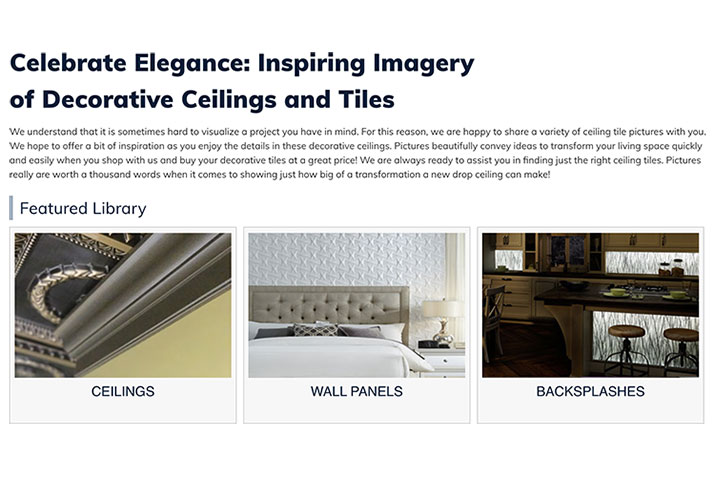

Transform Your Spaces with Stunning Decorative Ceiling Ideas

April 15, 2024

In the domain of architecture, engineering, and construction, the smallest details can make the most significant impact. One such detail often overlooked is the ceiling. However, with the array of decorative ceiling ideas offered by our featured client, Decorative Ceiling Tiles, your spaces can undergo a remarkable transformation, elevating them from ordinary to extraordinary.

At Decorative Ceiling Tiles, innovation meets aesthetics with a diverse range of options to suit both residential and commercial settings. Explore their Idea Library, a treasure trove of inspiration featuring captivating galleries showcasing various applications such as faux wood beams, lumisplash, bamboo pulp, and more. Whether you're envisioning a cozy bedroom retreat or designing an inviting office space, their Idea Library has you covered.

Introducing Innovate Building Solutions' Laminate Shower & Bathroom Wall Panels: Elevate Your Architectural Designs

April 11, 2024

Unveiling Innovate Building Solutions' Revolutionary Solution for Architects - In the domain of architectural design, particularly for multi-family apartments, homes, and hotels, the quest for innovative, durable, and visually captivating bathroom solutions has never been more pressing. Enter Innovate Building Solutions' Laminate Shower & Bathroom Wall Panels—a paradigm-shifting alternative that transcends the limitations of traditional materials, offering unparalleled versatility, aesthetics, and ease of maintenance.

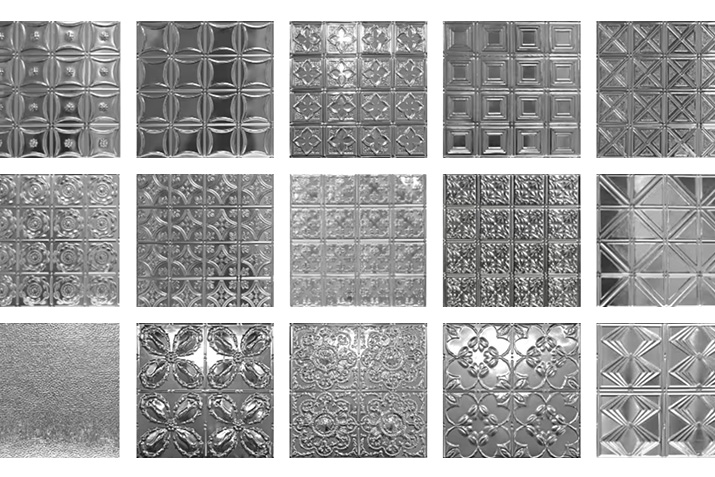

Tin Ceiling Pattern Charts

February 28, 2024

Shanko tin ceiling tiles, available at decorativeceilingtiles.net, are renowned for their quality and decorative appeal. These tiles are often used to enhance the aesthetic appeal of homes, commercial spaces, or historic buildings. Here's an overview of key features and benefits: