Finishes

Decorative Ceiling Tiles Highlights Three Interior Design Trends

August 26, 2025

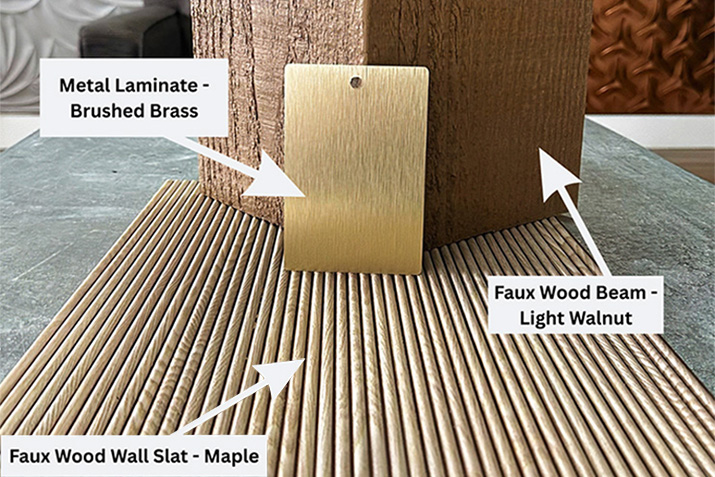

Interior design continues to evolve, blending timeless materials with modern innovations to create spaces that are both stylish and functional. Certain elements are experiencing renewed popularity, offering versatile solutions for residential and commercial interiors alike. DecorativeCeilingTiles.net identifies three standout trends that are shaping the design landscape in 2025.

StonePly Stone Panels: The Ultimate Solution for Modern Stone Cladding

December 6, 2024

StonePly stone panels revolutionize traditional stone cladding with their unique blend of natural beauty, strength, and advanced engineering. Whether you’re designing a skyscraper or a boutique interior, StonePly offers unmatched benefits.

Elite Crete Systems Specialty Flooring for Breweries, Wineries and Distilleries

October 9, 2024

The brewing, winemaking and distillery industries face unique challenges when it comes to flooring. Our flooring systems are thermal shock resistant to withstand forced steam and boiling water cleaning methods. These surfaces are slip resistant and offer chemical and stain resistance to common industrial cleaners and sterilizers. They offer a variety of options to meet the individual needs of your facility while being FDA, USDA and CFIA acceptable.

Sto Corp. Launching Sto Strike Defense to Defend Against Blunt Force Impacts

July 15, 2024

Sto Corp., the innovative world leader in claddings, air barriers, coatings, and restoration systems, announces the launch of Sto Strike Defense, an ultra-high impact puncture resistant solution designed to protect EIFS (Exterior Insulation and Finish Systems) from punctures caused by woodpeckers, as well as blunt and sharp objects.

Introducing the REFLECTOR™ Enhancer Flooring Systems for Architects

August 25, 2023

Elevate your architectural designs with the innovative REFLECTOR™ Enhancer Flooring System by Elite Crete Systems. Crafted exclusively for the discerning needs of commercial, industrial, and residential spaces, this specialty, high-build, self-leveling, and fluid-applied floor coating opens the door to a world of possibilities. When your project demands a flooring solution that seamlessly blends durability, longevity, aesthetics, ease of maintenance, and complete customization, the REFLECTOR™ system stands ready to meet and exceed your expectations. To ensure optimal results and capture the distinct essence of these flooring systems, we recommend engaging with our technical experts before installation or specification.

3 Retail Flooring Options

May 30, 2023

Retail clients can offer some of the best opportunities for flooring contractors. These projects typically involve significant square footage, generous budgets, and the potential for follow-up projects—during a shopping mall renovation or location expansion, for example. But what are the best retail flooring options to propose to a client? Here we look at three versatile retail flooring options suitable for locations like department stores, grocery stores, clothing stores, bookstores, and convenience stores.

Concrete surface restoration

February 23, 2023

Concrete surfaces require durable and long-lasting performance in parks and public spaces. These exterior repair coatings must withstand high traffic and extreme weather conditions, including abuse from snow removal equipment and de-icing salts and chemicals. These finishes also maintain color and appearance despite being exposed to extreme UV.

Electrostatic Dissipative Flooring - Before & After

November 2, 2022

Sensitive electronics manufacturing facilities specify flooring in the dissipative range 1×10/6 – 1×10/9 ohms. Ohms = Resistance to Electrical Flow. In industries where electronic components are involved, static electricity can cause damage to electronic components, readings and data. Conduction through fingertips is the most common form for static electricity, while induction is the transfer of static electricity between certain types of materials.

Custom flooring solutions for commercial spaces offer endless design options

October 3, 2022

Elite Crete Systems custom flooring solutions for commercial and retail spaces offer endless design options to meet your interior design requirements and durability needs. These seamless surfaces are fluid-applied in place and can be installed with minimal downtime. Not only can these flooring systems match your brand’s color scheme they can also be designed to incorporate your company’s logo. These coatings can achieve coefficient of friction (COF) to meet or exceed ADA Flat Surfaces, ADA Inclined Surfaces, OSHA and NFPA requirements.

Surface Protection with Anti-Graffiti Powder Coating

August 8, 2022

A masterpiece by the artist that causes considerable damage for those affected. Maliciously sprayed graffiti and the resulting damage to property pose a costly challenge.

What is the Best Resinous Coating for Garage Floors - Epoxy, Polyurethane, or Polyaspartic?

March 23, 2022

Epoxy resins have been used to coat garage floors for over a decade. In contrast, polyurethane (polyurea) and polyaspartic resins are relatively new. All three resinous coatings are highly durable, and each has advantages and disadvantages. Epoxy resins are used extensively in heavy-duty industries and are easier to install due to their slower setting time. Polyurea and Polyaspartic coatings provide a faster return-to-service than Epoxy. Polyaspartic coatings provide resistance against fading due to the sun’s UV rays. So, how do you decide which type of coating to use for your garage floor project? There are several considerations.

How Important is Wellness in Your Designs?

November 3, 2021

Good acoustics, access to natural light, pleasing aesthetics, and sustainable materials all play a role in adding wellness to your designs. Yet in any business or residential environment, indoor air quality (IAQ) may have the most important effect on an individual’s productivity and health.

HERMETIC™ Flake Flooring Systems for commercial, industrial and residential spaces

October 29, 2021

The HERMETIC™ Flake Flooring System is a durable, seamless, chemical resistant floor providing adjustable levels of slight texture and color to match any design theme or surroundings. This aesthetic floor includes multi-colored vinyl flakes (size options available) imbedded and fused between product layers providing an appealing look and increase slip resistance.

Sherwin-Williams 2022 Colormix® Forecast's Method palette

September 29, 2021

With influences from the art deco era and modern organic design, the 2022 Colormix® Forecast's Method palette brings warmth to workspaces and restaurants alike. Explore all the colors in this collection:

TIGER Drylac® powder coatings for agricultural and construction machinery

September 10, 2021

Today, about one-third of the earth's surface area is used for agriculture and forestry. Technological progress is also advancing in the agricultural industry. Agricultural machinery that assists with farming and harvesting is becoming increasingly functional and high-quality. TIGER Drylac® powder coatings help our customers maintain the quality and durability of their agricultural machinery for decades.

Sherwin-Williams Living Well™ Collection: Reflect

August 30, 2021

Explore the possibilities of neutrals with the Reflect palette from the Sherwin-Williams Living Well™ collection, full of airy whites and soft grays. See the full color collection:

The Reflector™ Enhancer Flooring System - a specialty, high build, self-leveling, fluid-applied floor coating

August 9, 2021

The REFLECTOR™ Enhancer Flooring System is a specialty, high build, self-leveling, fluid-applied floor coating. Engineered for commercial, industrial and residential applications where a durable, long-lasting, aesthetically unique, easy to maintain and completely custom floor is required. Due to the unique and unrepeatable nature of these flooring systems, consult with a technical representative before installing or specifying.

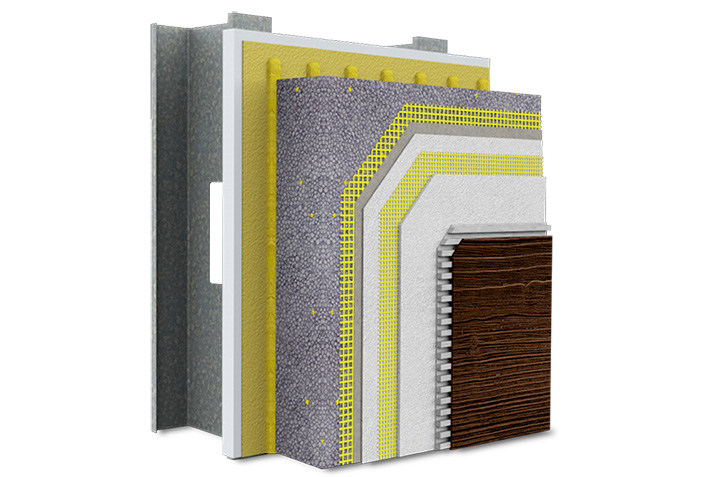

Houston House: StoTherm® ci with Stolit® Milano finish provides comfort and visual appeal

July 7, 2021

The East Village is one of New York City’s trendiest neighborhoods, and Houston Street is one of the busiest thoroughfares. For the Houston House project, Jeffrey Cole of Jeffrey Cole Architects needed a design that was stylish enough for the East Village residents who would call it home while simultaneously addressing the issues that come with traffic noise. And that’s before we even begin talking about dealing with New York City’s blustery winters and brutal summers. Through creative design, clever use of the StoTherm ci exterior wall system and expert application of a Stolit Milano finish, Cole made quick work of all three challenges in spectacularly successful fashion.

June's Color of the Month: Commodore (SW 6524)

June 30, 2021

June’s Color of the Month, Commodore SW 6524 (185-C7), creates a wave of clarity and calm. Coordinating colors and wood, black and brass finishes combine effortlessly to further the hue’s feeling of comfort.

Benefits of Anodized Powder Coatings

June 7, 2021

When faced with the question to used anodized substrates or an anodized effect powder coating -what would you choose? There are advantages in both, but this article highlights the benefits of the anodized powder coating effect. When considering why to convert to the powder coating anodized effect one should understand the anodizing process and its limitations.