Looking for better fire-rated horizontal membrane assemblies?

August 11, 2021

Read the full original article here: https://www.nationalgypsum.com/newsroom/newsletters/onboard-june2021#

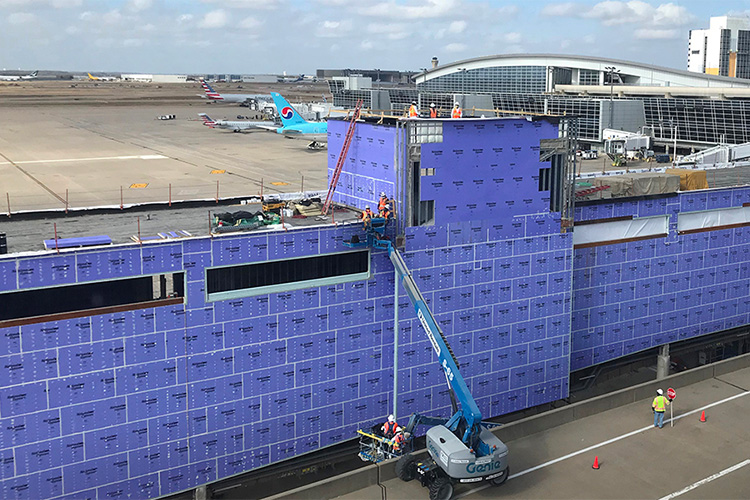

Dallas Fort Worth International Airport Terminal F uses Gold Bond® products

As an architect, you’re often confronted with providing fire-rated horizontal assemblies in your designs. Sometimes it isn’t feasible to construct a full fire-rated floor- or roof-ceiling assembly based on existing conditions, or it isn’t possible to construct new walls up to existing rated assemblies due to height restrictions or physical obstructions, such as piping and ductwork.

NGC Fire-Rated Horizontal Assemblies

To address these common design and installation issues, National Gypsum Company has developed a series of fire-rated horizontal assemblies (non-loadbearing). These are constructed with framing and gypsum board and without the associated floor or roof component found in UL floor- and roof-ceiling assemblies.

Common applications – where you’ll find them especially useful for horizontal membrane assemblies – include corridor and stair ceilings, elevator hoistways, stair soffits, protected plenums, and duct enclosures.

“Horizontal membranes are invaluable when renovating existing buildings,” says Jim Farrell, National Gypsum Company Construction Services manager. “The fire rating of the deck above is often inadequate or it can’t be accessed due to plumbing and HVAC equipment.”

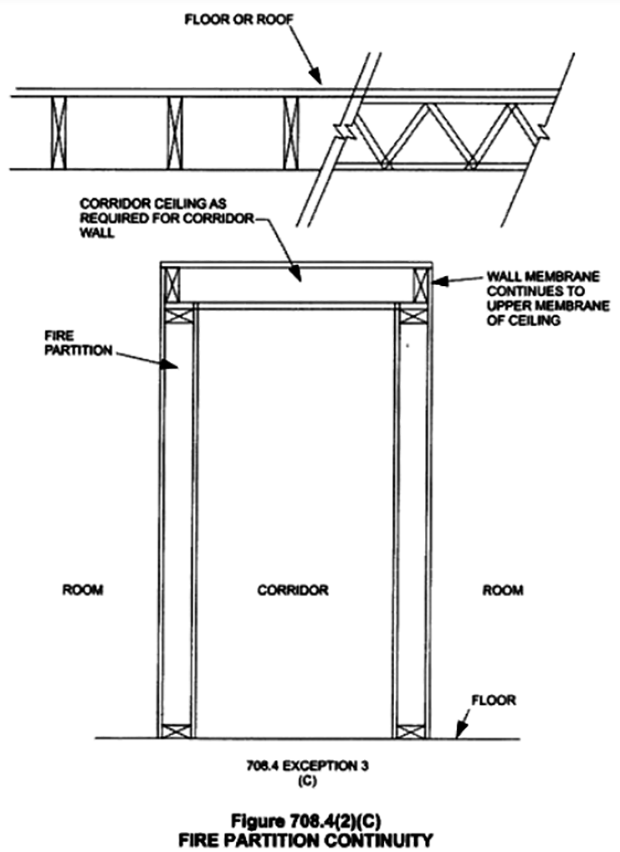

Before fire-rated horizontal membranes were developed, egress corridor ceilings were typically constructed with a fire-rated wall assembly turned horizontally. This is the only instance in the International Building Code (IBC) that allows an assembly that was tested vertically as a wall to be used in a horizontal application.

Shaftwall systems were commonly used because they could be constructed from the bottom only. National Gypsum Company’s Shaftwall Evaluation Report, UL ER R3501-02, affirms code compliance of 1- and 2-hour shaftwall assemblies for use as corridor ceilings.

Why NGC Developed Them and the UL Designs

Realizing the life-safety issues, construction problems, and limitation of use to corridors, National Gypsum Construction Services began developing fire-rated assemblies that were tested horizontally. These UL designs can be installed in egress corridors as well as other applications where the fire-rated walls do not extend vertically to a fire-rated floor or roof assembly.

Krista Karlson, AIA, LEED AP, chief practice officer of SGA | NarmourWright Design in Charlotte, N.C., appreciates the additional assembly options National Gypsum offers. As she says: “Instead of relying on a code allowance for corridor ceilings, I prefer knowing the systems I’m using for my life-safety plans are actually fire-tested. Thanks, National Gypsum!”

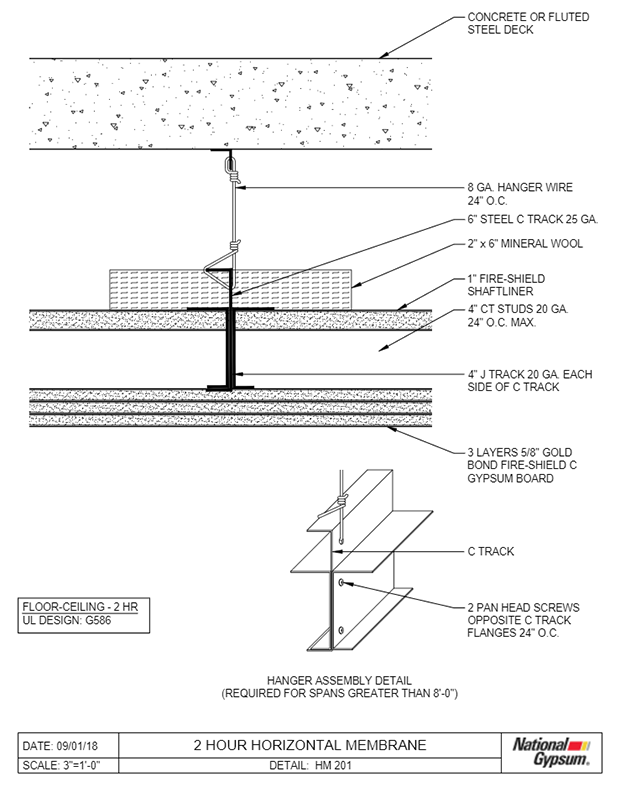

National Gypsum pioneered the development of fire-rated horizontal membranes with UL design G586. This 2-hour horizontal shaftwall assembly consists of 4” shaftwall studs with shaftliner panels between each stud and three layers of 5/8” Type C gypsum board applied to the underside of the framing. UL design G586 can span 8’-0” from wall to wall or indefinitely when used in conjunction with the hanger assembly.

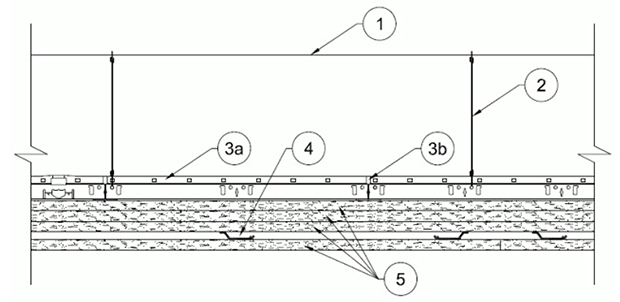

For 1-hour assemblies, National Gypsum developed UL design I504, which is a 1-hour horizontal assembly that consists of 3-5/8” steel studs 16” o.c. with three layers of 5/8” Type X gypsum board applied to the underside of the framing. UL design I504 can also span 8’-0” from wall to wall or indefinitely when used in conjunction with the hanger assembly (shown below). As an option, I504 allows for the use of a premanufactured suspended grid system in lieu of the steel stud framing.

03

As an alternate to UL design G586, 2-hour horizontal shaftwall, UL design K504, allows for the use of four layers of Type X gypsum board applied to a premanufactured suspended grid system with resilient channels between the third and fourth layers.

@NationalGypsum #NationalGypsum #construct

Company:  National Gypsum

National Gypsum

Product: Gold Bond Building Products

Of: Frank Fuller & Pat Grotlisch

Source: https://www.nationalgypsum.com/newsroom/newsletters/onboard-june2021#

Tags:

Building

Houston House: StoTherm® ci with Stolit® Milano finish provides comfort and visual appeal (July 7, 2021), Flashing Components (September 28, 2020), Building Peace of Mind with Hurricane Resistant Solutions (September 9, 2020), Integrating security into the growing smart building market (April 15, 2019), Architectural Trends for 2019 (February 21, 2019), How to Fluid-Proof Circular Joints in Concrete (March 26, 2018), Understanding the five phases of design (March 18, 2018), Translucent Panels | Chesapeake Boathouse, Oklahoma City (October 31, 2017)