Understanding PUR and PIR Insulation: Performance and Applications by Kingspan

August 20, 2025

Maximize Building Efficiency with Kingspan Insulation Solutions

Discover the difference that high-performance insulation can make. Kingspan’s range—from Insulation Boards and Insulated Sheathing to House Wraps and Roofing Cover Boards—delivers superior thermal performance, moisture protection, and durability for walls, roofs, and foundations. Upgrade your building envelope with solutions designed to keep structures energy-efficient, safe, and long-lasting.

Polyurethane-based insulations, including PUR and PIR, share a similar chemical foundation but differ in performance characteristics. Both materials are lightweight and offer low thermal conductivity, making them effective at reducing energy consumption for heating and cooling in buildings.

The Chemistry Behind PUR and PIR

PUR (polyurethane) foams are created by reacting a polyol component with an isocyanate (iso) component. The hydroxyl (OH) groups of the polyol chemically link with the isocyanate (NCO) groups to form urethane bonds. PIR (polyisocyanurate) foams, on the other hand, involve trimerization reactions of the iso components, creating isocyanurate structures. Excess iso in PIR reacts with polyol to form additional urethane linkages, enhancing thermal stability and fire resistance.

Historical Development

Both PUR and PIR originated from polyurethane, a plastic first developed in 1937 by German chemist Otto Bayer and his team. The introduction of water to polyurethane in 1954 led to rigid PUR, suitable for insulation applications. In 1967, PIR was developed by modifying PUR’s chemical reactions at higher temperatures, resulting in improved thermal and fire performance.

Applications and Benefits of PUR

- Energy Efficiency: PUR can be injected into wall cavities, filling small gaps and creating an airtight barrier that enhances building energy performance.

- Versatility: The foam can be sprayed onto a variety of surfaces, making it a practical and cost-effective choice for renovations.

- Water Resistance: PUR’s low moisture absorption helps protect structures in flood-prone areas by minimizing water damage within walls.

Advantages of PIR Insulation

- High Thermal Performance: PIR boards provide excellent insulation with only half the thickness required by conventional mineral-based products.

- Moisture Barrier: Like PUR, PIR resists moisture, contributing to building longevity.

- Enhanced Fire Resistance: PIR is more resistant to flames and smoke than PUR, slowing fire spread and reducing smoke emissions.

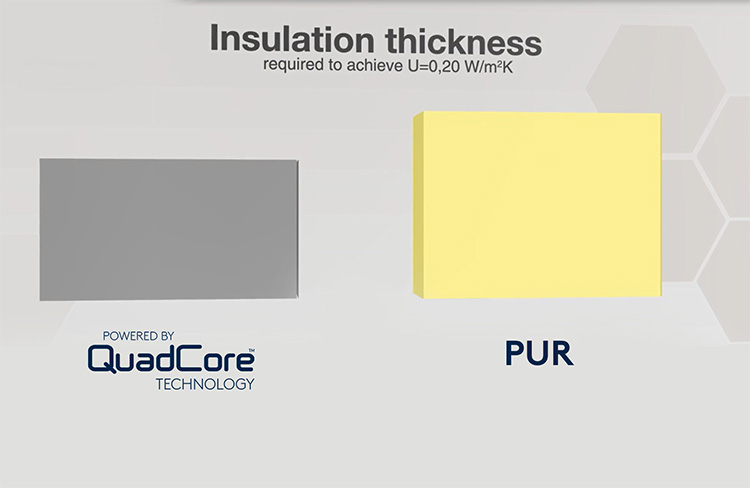

The Next Generation: Kingspan QuadCore®

While PUR and PIR remain widely used, Kingspan’s QuadCore® technology represents a significant advancement in insulation. QuadCore delivers up to 11% better thermal performance than PIR and up to 60% improvement over standard PUR, while meeting stringent fire safety standards. It is available in a variety of insulated metal panel solutions designed for superior energy efficiency and building protection.

Learn more about QuadCore insulation: QuadCore Technology

Download detailed product information: QuadCore Brochure (PDF)

Explore Kingspan’s PIR and QuadCore panel options, including:

- QuadCore® KS Series: Panels offering distinctive aesthetics through various profile designs.

- QuadCore® Optimo®: Modern, flat panels designed for visually appealing building envelopes.

- QuadCore® Designwall 4000: Large-scale panel solution for expansive projects.

Original article: PUR vs. PIR: Know the Difference

@KingspanIns_US #KingspanIns_US #Kingspan #Insulation #MoistureManagement

Company:  Kingspan Insulation LLC

Kingspan Insulation LLC

Product: Insulation Boards

Source: https://www.kingspan.com/us/en/knowledge-articles/pur-vs-pur

Tags: